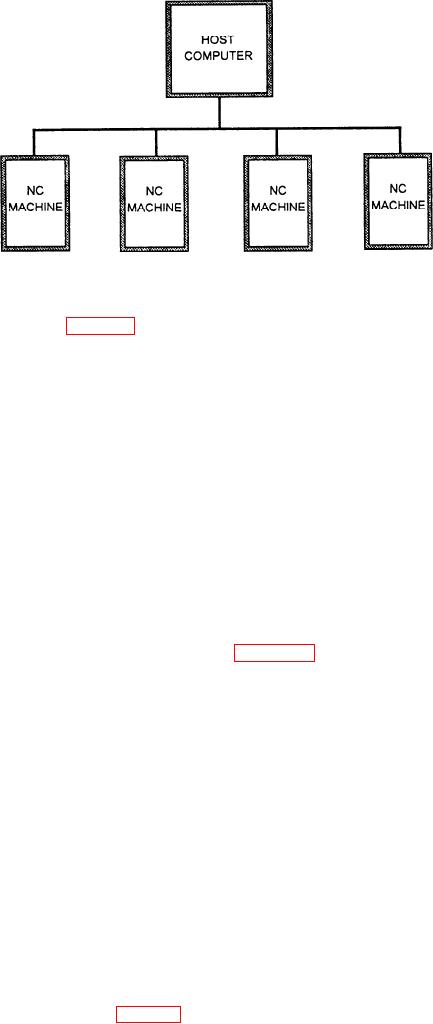

Figure 11-5.--Direct numerical control.

design a part. The computer is used to place the design

elements (lines, curves, circles, and so on) and

machine has a slant bed. The slant bed allows the chips

dimensions on the computer display screen.

to fall into the chip pan, rather than on tools or bedways.

Despite this odd appearance, the slant bed CNC lathe

The machinist defines the geometry of the part to

functions just like a conventional lathe.

the computer using one or more input devices. These

devices may be the keyboard, a mouse, a digitizer, or a

As with CNC milling machines, you must have the

pen light. When the design has been edited and proofed,

controller manual for your machine's controller to

the computer can be instructed to analyze the geometry

program it and operate the machine.

of the part and calculate the tool paths that will be

required to machine the part. Each tool path is translated

CNC TOOLING

into a detailed sequence of machine axes movement

commands that will enable a CNC machine tool to

There are many different tool-holding devices used

produce the part. No engineering drawing is required.

for CNC machines. They can be as simple as a quick-

change tool post or as complicated as an automatic tool

The computer-generated instructions can be stored

change system, but they all serve the same purpose. The

in a central computer for direct transfer to a CNC

tool-holding devices for each shop will vary since each

machine tool for parts manufacture as shown in

machine comes with different tooling and because shop

personnel will purchase the tooling they prefer.

(DNC). The data also can be stored on disk for future

use.

Cutting tools are available in three basic material

types: high-speed steel, tungsten carbide, and ceramic.

The system that makes all this possible is computer-

Since we covered cutting tools in chapter 5, we will only

aided design/computer-aided manufacturing (CAD/

briefly discuss them now. High-speed steel is generally

CAM). There are several CAD/CAM software

used on aluminum and other nonferrous alloys, while

programs. They are constantly being upgraded and

tungsten carbide is used on high-silicon aluminums,

made more user friendly.

steels, stainless steels, and exotic metals. Ceramic

To state it simply, CAD is used to draw the part and

inserts are used on hard steels and exotic metals.

to define the tool path. CAM is used to convert the tool

Inserted carbide tooling is becoming the preferred

path into codes that the computer on the machine can

tooling for many CNC applications.

understand.

COMPUTER-AIDED

NUMERICAL CONTROL SYSTEMS

DESIGN/COMPUTER-AIDED

MANUFACTURING

A CNC machine consists of two major components:

the machine tool and the controller, which is an onboard

Computer technology has reached the stage where

computer. These components may or may not be

11-5