are bolted to it so that they support the engine at three

or four points. These points of contact usually are

cushioned with rubber that insulates the frame and the

body of the vehicle from engine vibration and therefore

prevents damage to the engine supports and the

transmission.

Exhaust Manifold

The exhaust manifold is a tube that carries waste

products of combustion from the cylinders. On L-head

engines the exhaust manifold is bolted to the side of the

engine block on; overhead-valve engines it is bolted to

the side of the engine cylinder head. Exhaust manifolds

may be single iron castings or may be cast in sections.

They have a smooth interior surface with no abrupt

change in size (see fig. 12-1 1).

Intake Manifold

The intake manifold on a gasoline engine carries the

fuel-air mixture from the carburetor and distributes it as

evenly as possible to the cylinders. On a diesel engine,

the manifold carries only air to the cylinders. The intake

manifold is attached to the block on L-head engines and

to the side of the cylinder head on overhead-valve

engines. (See fig. 12-11.)

In gasoline engines, smooth and efficient engine

performance depends largely on whether the fuel-air

mixtures that enter each cylinder are uniform in

strength, quality, and degree of vaporization. The inside

walls of the manifold must be smooth to offer little

obstruction to the flow of the fuel-air mixture. The

manifold is designed to prevent the collecting of fuel at

the bends in the manifold.

The intake manifold should be as short and straight

as possible to reduce the chances of condensation

between the carburetor and cylinders. Some intake

manifolds are designed so that hot exhaust gases heat

their surfaces to help vaporize the fuel.

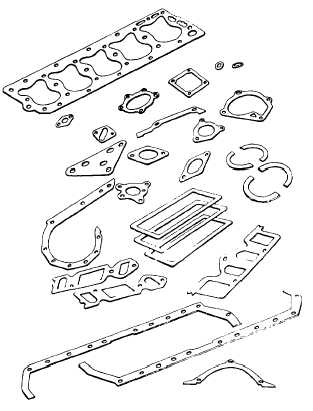

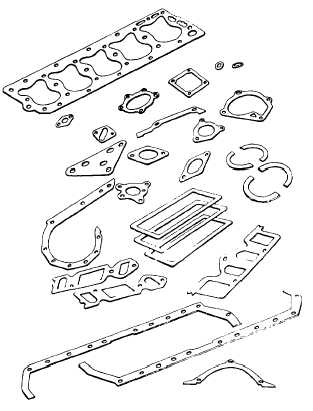

Gaskets

The principal stationary parts of an engine have just

been explained. The gaskets (fig. 12- 12) that serve as

seals between these parts require as much attention

during engine assembly as any other part. It is

impractical to machine all surfaces so that they fit

together to form a perfect seal. The gaskets make a joint

that is air, water, or oil tight. Therefore, when properly

Figure 12-12.-Engine overhaul gasket kit.

installed, they prevent loss of compression, coolant, or

lubricant.

MOVING PARTS OF AN ENGINE

The moving parts of an engine serve an important

function in turning heat energy into mechanical energy.

They further convert reciprocal motion into rotary

motion. The principal moving parts are the piston

assembly, connecting rods, crankshaft assembly

(includes flywheel and vibration dampener), camshaft,

valves, and gear train.

The burning of the fuel-air mixture within the

cylinder exerts a pressure on the piston, thus pushing it

down in the cylinder. The action of the connecting rod

and crankshaft converts this downward motion to a

rotary motion.

Piston Assembly

Engine pistons serve several purposes. They

transmit the force of combustion to the crankshaft

through the connecting rod. They act as a guide for the

upper end of the connecting rod. And they also serve as

12-13