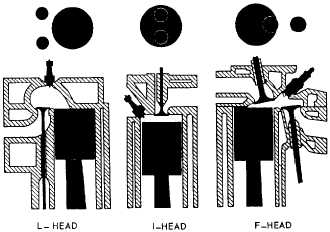

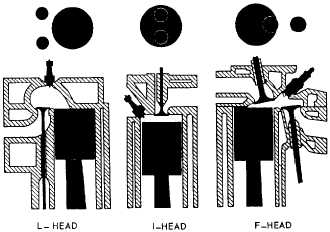

Figure 12-8.-L-, I-, and F-valve arrangement.

I-Head

Engines using the I-head construction are called

valve-in-head or overhead valve engines, because the

valves mount in a cylinder head above the cylinder. This

arrangement requires a tappet, a push rod, and a rocker

arm above the cylinder to reverse the direction of the

valve movement. Only one camshaft is required for both

valves. Some overhead valve engines make use of an

overhead camshaft. This arrangement eliminates the

long linkage between the camshaft and the valve.

F-Head

In the F-head engine, the intake valves normally are

located in the head, while the exhaust valves are located

in the engine block. This arrangement combines, in

effect, the L-head and the I-head valve arrangements.

The valves in the head are actuated from the camshaft

through tappets, push rods, and rocker arms (I-head

arrangement), while the valves in the block are actuated

directly from the camshaft by tappets (L-head

arrangement).

ENGINE CONSTRUCTION

Basic engine construction varies little, regardless of

the size and design of the engine. The intended use of

an engine must be considered before the design and size

can be determined. The temperature at which an engine

will operate has a great deal to do with the metals used

in its construction.

The problem of obtaining

service parts in the field

categorization of engines

servicing procedures and

are simplified by the

into families based on

construction and design. Because many kinds of engines

are needed for many different jobs, engines are designed

to have closely related cylinder sizes, valve

arrangements, and so forth. As an example, the General

Motors series 71 engines may have two, three, four, or

six cylinders. However, they are designed so that the

same pistons, connecting rods, bearings, valves and

valve operating mechanisms can be used in all four

engines.

Engine construction, in this chapter, will be broken

down into two categories: stationary parts and moving

parts.

STATIONARY PARTS

The stationary parts of an engine include the

cylinder block, cylinders, cylinder head or heads,

crankcase, and the exhaust and intake manifolds. These

parts furnish the framework of the engine. All movable

parts are attached to or fitted into this framework.

Engine Cylinder Block

The engine cylinder block is the basic frame of a

liquid-cooled engine, whether it is the in-line,

horizontally opposed, or V-type. The cylinder block and

crankcase are often cast in one piece that is the heaviest

single piece of metal in the engine. (See fig. 12-9.) In

small engines, where weight is an important

consideration, the crankcase may be cast separately. In

most large diesel engines, such as those used in power

plants, the crankcase is cast separately and is attached to

a heavy stationary engine base.

In practically all automotive and construction

equipment, the cylinder block and crankcase are cast in

one piece. In this course we are concerned primarily

with liquid-cooled engines of this type.

The cylinders of a liquid-cooled engine are

surrounded by jackets through which the cooling liquid

circulates. These jackets are cast integrally with the

cylinder block. Communicating passages permit the

coolant to circulate around the cylinders and through the

head.

The air-cooled engine cylinder differs from that of

a liquid-cooled engine in that the cylinders are made

individually, rather than cast in block. The cylinders of

air-cooled engines have closely spaced fins surrounding

the barrel; these fins provide an increased surface area

from which heat can be dissipated. This engine design

is in contrast to that of the liquid-cooled engine, which

has a water jacket around its cylinders.

12-9