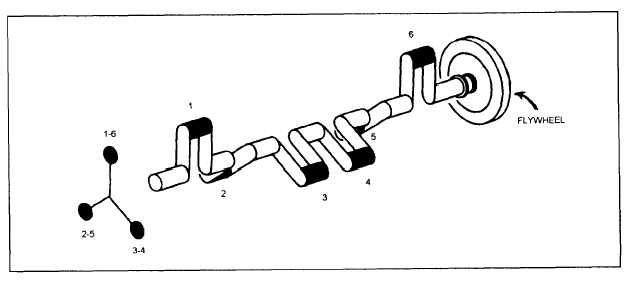

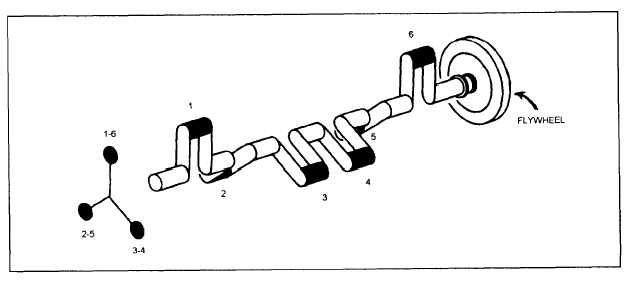

Figure 12-6.-Crankshaft for a six-cylinder engine.

MULTIPLE-CYLINDER ENGINES

The discussion so far in this chapter has concerned

a single-cylinder engine. A single cylinder provides only

one power impulse every two crankshaft revolutions in

a four-cycle engine. It delivers power only one-fourth

of the time. To provide for a more continuous flow of

power, modem engines use four, six, eight, or more

cylinders. The same series of cycles take place in each

cylinder.

In a four-stroke cycle, six-cylinder engine, for

example, the cranks on the crankshaft are set 120

degrees apart. The cranks for cylinders 1 and 6, 2 and 5,

and 3 and 4 are in line with each other (fig. 12-6). The

cylinders fire or deliver the power strokes in the

following order: 1-5-3-6-2-4. Thus, the power strokes

follow each other so closely that a continuous and even

delivery of power goes to the crankshaft.

TIMING

In a gasoline engine, the valves must open and close

at the proper times with regard to piston position and

stroke. In addition, the ignition system must produce the

sparks at the proper time so that the power strokes can

start. Both valve and ignition system action must be

properly timed if good engine performance is to be

obtained.

Valve timing refers to the exact times in the engine

cycle that the valves trap the mixture and then allow the

burned gases to escape. The valves must open and close

so that they are constantly in step with the piston

movement of the cylinder they control. The position of

the valves is determined by the camshaft; the position

of the piston is determined by the crankshaft. Correct

valve timing is obtained by providing the proper

relationship between the camshaft and the crankshaft.

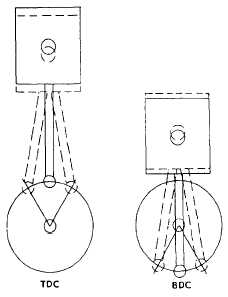

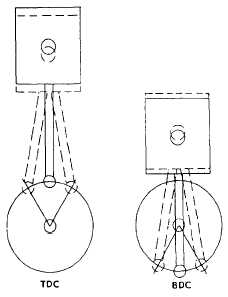

When the piston is at top dead center, the crankshaft

can move 15° to 20° without causing the piston to move

up and down any noticeable distance. This is one of the

two rock positions (fig. 12-7) of the piston. When the

piston moves up on the exhaust stroke, considerable

momentum is given to the exhaust gases as they pass out

through the exhaust valve port. If the exhaust valve

closes at top dead center, a small amount of the gases

Figure 12-7.-Rock position.

12-7