When H2O combines with R- 12 it forms sulfric

acid which will attack the entire system. Good

engineering practice dictates that evacuation,

dehydration and fixing all air leaks will in the long

term prevent an acid attack upon the system.

evacuation process. If possible, the dehydrated

air should be heated to about 240°F.

Large dehydrators, suitable for preliminary

dehydration of refrigeration systems, are usually

available at naval shipyards and aboard tenders

and repair ships.

Where moisture accumulation must be cor-

rected, the system should first be cleared of

refrigerant and air. The time required for these

processes will depend upon the size of the system

and the amount of moisture present. It is good

engineering practice to circulate heated air

through a large dehydrator for several hours,

or as long as the dehydrator drying agent

remains effective, before proceeding with the

After the preliminary dehydration, the remain-

ing moisture is evacuated by means of a two-stage

high-efficiency vacuum pump. (These vacuum

pumps are available aboard tenders and repair

ships.)

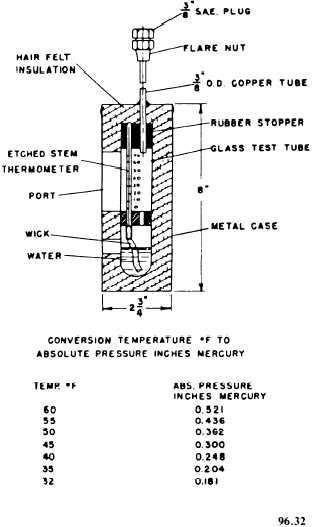

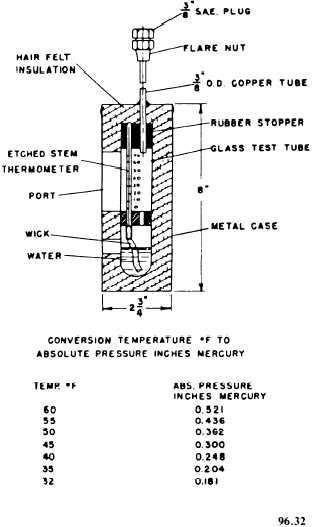

A vacuum indicator (figure 6-9) is attached to

the two-stage high efficiency pump. It consists of

an insulated test tube containing a wet bulb ther-

mometer with its wick immersed in distilled water.

This indicator is connected to the vacuum pump

suction line, which in turn, is connected to the

refrigeration system. The refrigerant circuit should

be closed to the atmosphere and the charging con-

nection should be opened to the vacuum pump.

Two-stage pumps are started for operation in

PARALLEL so that maximum displacement may

be obtained during the initial pump-down stages.

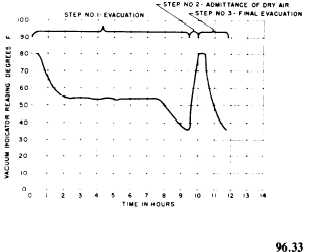

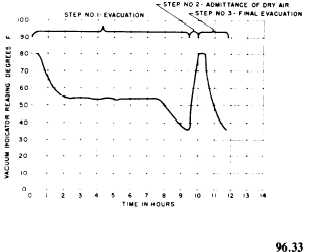

When the indicator shows a temperature of about

55 °F (0.43 inch Hg, absolute), the pumps are

placed in SERIES operation (wherein the

discharge from the first step enters the suction of

the second step pump). The dehydration process

will be reflected in the temperature drop of the

vacuum indicator (as shown in figure 6-10).

Readings will initially reflect ambient

temperatures. Then they will show rapidly

Figure 6-10.—Vacuum indicator readings plotted during

Figure 6-9.—Dehydrator vacuum indicator.

dehydration.

ENGINEMAN 1 & C

6-14