Chapter 3—ENGINE MAINTENANCE

cutout mechanism, or a loss of compression. If,

after checking the air cleaner, the filter, and the

fuel cutout mechanism, you determine that the

problem is due to loss of compression, then you

must perform a compression check with a cylinder

pressure indicator.

There are several different types of indicators

that may be used. Most indicators used with

diesel-cylinder engines are either of the spring

balanced type or the trapped pressure type. They

are manufactured by various companies such as

Kiene, Bacharach, and Kent-Moore. Some of

these indicators measure only compression

pressure, others measure both compression and

firing pressures.

Spring Balanced Indicator

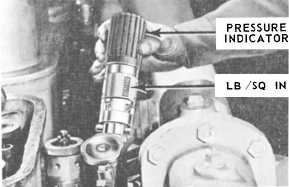

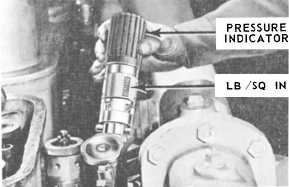

A spring balanced indicator, such as the one

manufactured by Bacharach (figure 3-1), employs

a spherical ball piston, which is held on its seat

by the force of a helical spring actuated by the

cylinder pressure which acts against the bottom

of the ball piston to oppose the spring tension.

Before the indicator is attached to the engine, the

vulcanized handle must be rotated clockwise

until the reading on the counter is greater than

the maximum cylinder pressure expected. The

amount of this pressure is listed in the engine

manufacturer’s technical manual. When the

indicator is installed, the operator must make sure

that it is placed as near the cylinder as possible

and position it so that it can be read easily. After

the indicator is installed the engine is operated at

the specified rpm, then the fuel to the cylinder

Courtesy of Bacharach, Inc., USA

75.238X

Figure 3-1.-Spring balanced Pressure Indicator.

being tested is cut out, the cylinder test cock is

opened, and the spring tension on the indicator

is adjusted. The tension of the spring is reduced

b y r o t a t i n g t h e v u l c a n i z e d h a n d l e

counterclockwise until the maximum cylinder

pressure barely offsets the spring pressure. At this

point, the latch mechanism of the indicator trips

and locks the handle firmly in position, giving a

direct and exact reading of the pressure in pounds

per square inch (psi). To reset the lock mechanism

for a new reading, the handle must be rotated

counterclockwise one-fourth turn. When this in-

dicator is stowed for future use, the indicator

spring must be unloaded by rotating the handle

counterclockwise until a zero pressure reading is

obtained.

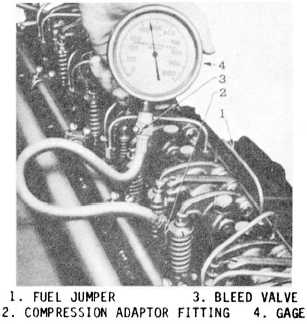

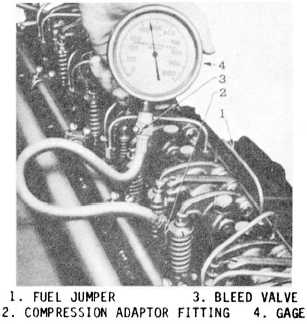

Trapped Pressure Indicators

In this type of indicator, the cylinder gases

enter past a valve into a chamber which leads to

a gage. When the pressure above the valve equals

that of the cylinder, the valve seats and traps the

gas above the valve at its highest pressure, then

this pressure is read on the gage. There are several

other types of indicators. The one pictured in

figure 3-2 is used to take compression readings

Courtesy of Bacharach, Inc., USA

75.238X

Figure 3-2.—Trapped Pressure Indicator (small boat).

3-3