4. Move the indicator toward the shaft until the

sensor button just touches the surface you wish to

measure.

5. Continue moving the indicator slowly toward

the shaft until the dial pointer has moved to the midpoint

of its travel on the dial face.

6. Leave the pointer at midtravel and turn the bezel

until the zero on the dial is aligned with the pointer.

7. You can now rotate and watch the pointer to see

if it moves. The total amount the pointer moves is called

the total indicator reading (TIR). If the shaft is straight,

the pointer should remain at zero.

Crankshaft End Play or Thrust Readings

To measure crankshaft end play or thrust, use the

following procedure:

1. Attach the dial indicator to a convenient place

near the vibration damper.

2. Position the dial indicator gauge so the contact

point touches the front of the vibration damper and

moves the dial indicator near the midpoint of its range.

3. Insert one end of a pry bar between a main

NOTE: DO NOT INSERT THE PRYBAR

BETWEEN THE VIBRATION DAMPER AND THE

BLOCK TO MEASURE THE CRANKSHAFT END

PLAY. You may dent the damper and render it

ineffective.

4. Move the crankshaft toward the dial indicator.

Be sure to maintain a constant pressure on the prybar.

5. Set the dial indicator to zero.

6. Remove the prybar and then reinsert it on the

other side of the main bearing cap.

7. Carefully pry the crankshaft in the opposite

direction to measure the crankshaft end play. Repeat

your measurement a minimum of two times for

accuracy.

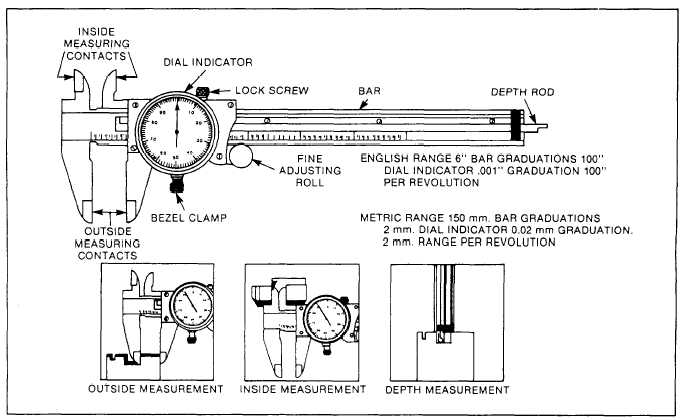

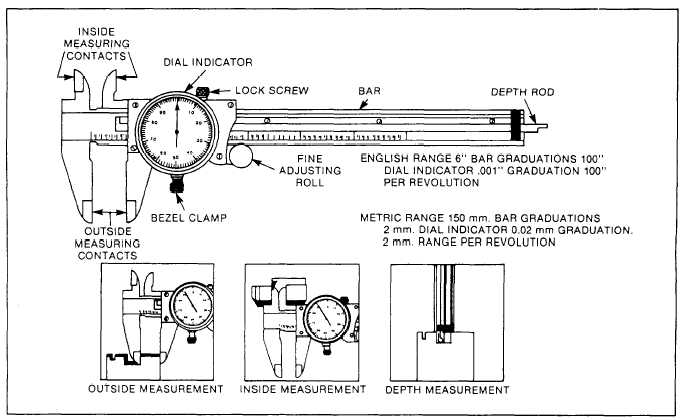

DIAL/VERNIER CALIPER

The dial/vernier caliper is used to measure the inside

or outside diameter of an object. Figure 2-2 shows a

typical dial/vernier caliper.

Most dial/vernier calipers have a slide, slide

lockscrew, thumb button, scale, dial with measured

bearing cap and a crankshaft counterweight.

increments of 0.001 inch, and a bezel.

Figure 2-2.—Typical dial/vernier caliper.

2-2