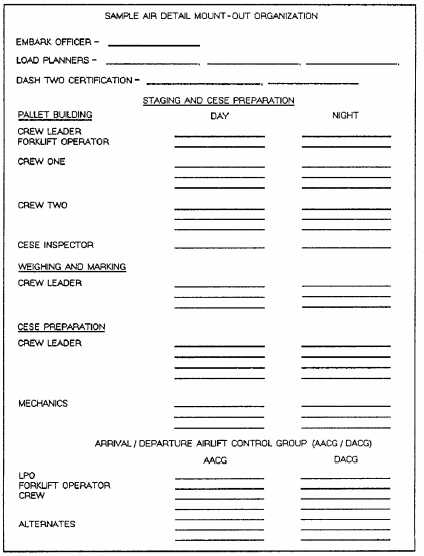

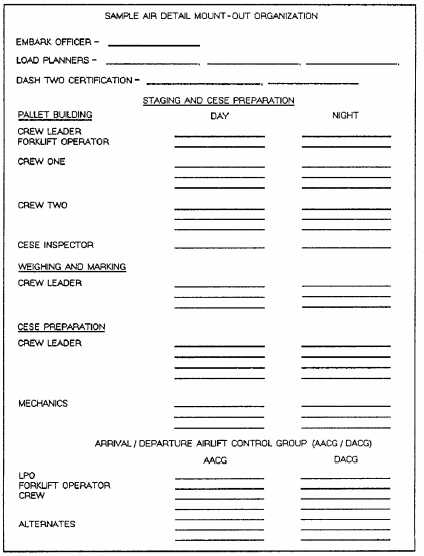

det should divide into two shifts (fig. 2-19) to achieve

maximum production and to avoid overworking the

troops.

The equipment platoon supervisor plays a

key role, along with the air det staff, when

prioritizing CESE and supplies to be mounted out.

Certain CESE and supplies, such as tractor and

trailers, forklifts, the maintenance field crew

truck, light plants, and various tools, are required.

These CESE and supplies are used to support the

building of pallets, disassembly of CESE,

breakdown of the camp, garbage runs, hauling of

CESE, and transport supplies and personnel to the

staging area. This movement from the campsite to

the airfield may require a tactical or nontactical

convoy procedure.

Another area the equipment supervisor must

consider is a productive method for washing and

preparing CESE for the mount-out. The task of

cleaning CESE is one that must not be overlooked

and should be addressed before deploying to the

mission site. The prepping of CESE in the field can be

a time-consuming task and, if not properly planned,

could result in not meeting the deadline for the joint

inspection.

An efficient means for washing CESE is to

locate a washrack or to build one. Some

considerations in selecting the location of the

washrack are as follows: the distance the CESE must

be driven once it has been washed, the amount of

water required to wash each piece of CESE (if using

the water truck), and the distance the water truck

must travel to obtain water.

A pressure washer located at the washrack is

desirable and should be augmented to the air det;

however, they are sometimes hard to obtain. Some

Figure 2-19.—Sample of the air det mount-out organization.

2-17