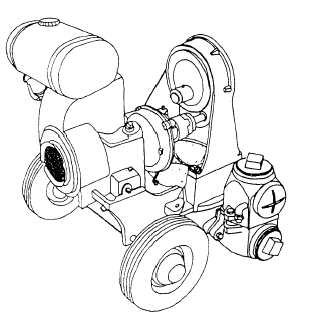

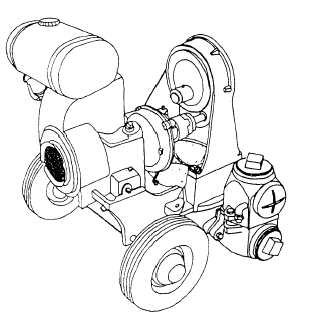

Figure 14-33.—Diaphragm pump.

unseat (and at the same time keeps the discharge ball

valve seated) and to admit liquid to the pump cylinder.

On the discharge stroke, the diaphragm is pushed

downward forcing the trapped liquid out through the

discharge valve. Thus the liquid is made to move by the

reciprocating motion of a flexible diaphragm.

Since the diaphragm forms a tight seal in the pump

cylinder between the liquid being pumped and the rest

of the pump and driving mechanisms, there is little

danger of liquid abrasion or corrosion of moving parts

behind the diaphragm.

NOTE: Diaphragm pumps are especially

well-suited for pumping mud, slime, silt, and other

wastes or heavy liquids containing debris, such as sticks,

stones, or rags.

Liquid strainers are fitted at the suction inlet to

prevent large objects from fouling the suction and

discharge valves or possibly damaging the diaphragm.

You may have to use the diaphragm pump for such

duties as dewatering trenches where sewer lines or

waterlines are to be laid, dewatering cofferdams or

cave-ins, or repairing breaks in water or sewage lines.

Two of the most popular types of diaphragm pumps are

the mud hog (closed discharge) and the water hog

(open discharge).

The mud hog is for jobs that require pumping heavy

and thick liquids that must be discharged at a distance

away from the pump. The pump is fitted with discharge

hose connctions, and the ball valves and chambers are

designed to prevent fouling by sticks, stones, or rags.

The water hog is used for pumping thinner or less

viscous liquids. It can handle liquids containing sand,

gravel, or mud. The discharge outlet from the water hog

is open to permit free flow and to increase discharge

capacity. The liquid is discharged directly at the pump.

A discharge hose, however, can be fitted to the pump if

desired, but the hose connection can reduce the

efficiency of the pump.

You must know the operation of the diaphragm

pump. Since nearly every job presents a different

problem, you may have to vary the operating procedure

to fit the individual job.

Before starting the pump, place the suction line and

screen in the liquid to be removed by the pump.

Construct a trough to drain the pump discharge away

from the pump.

OPERATION.— Start the engine first. If the pump

does not pick up the liquid in a minute or two, check the

suction line for leaks. You can do this by pouring water

over the hose connections. In the event there is a leak,

air bubbles will appear.

Should the connections be tight and no leaks appear,

check the diaphragm for cracks or punctures. If the

diaphragm is damaged, it has to be replaced. A

mechanic inspector must make any further inspections.

INSPECTION.— Because of the nature of the

liquids handled by diaphragm pumps, inspection during

pump operation becomes particularly important.

Inspect the suction inlet strainer often to avoid

accumulations of debris that reduce suction efficiency.

Most diaphragm pump installations also permit easy

access to the suction and discharge ball check valves.

These valve mechanisms should also be inspected

frequently to detect scoring, fouling, and improper valve

seating.

NOTE: Sand, gravel, and other material can

corrode the diaphragm and ball check valves; expect

these parts to require the most frequent operator

inspections.

Centrifugal Pump

The basic centrifugal pump has only one moving

part: a wheel or impeller that is connected to the drive

shaft of a prime mover and that rotates within the pump

casing. The impeller is designed to impart a whirling or

revolving motion to the liquid in the pump. When the

impeller rotates at relatively high speeds, sufficient

14-29