Figure 1-21 .—Fuel filter elements.

contain more gum and abrasive particles that can cause

premature wear of injection equipment. Some diesel

fuel filters have an air valve to release any air that

accumulates in the filter during operation.

Most diesel engine designs include two filters in the

fuel supply system: a primary filter and a secondary

filter.

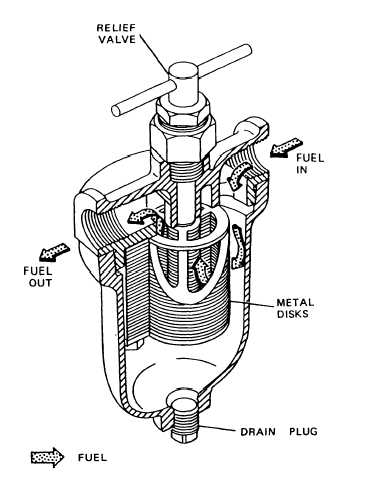

PRIMARY FILTER.— In most designs, the

primary filter is located between the fuel tank and the

fuel supply pump. A primary falter contains a coarse

filter material that removes the larger foreign matter.

They are metal filters and only allow fine particles to

pass through them (fig. 1-22). Solid materials larger

than 0.005 inch remain outside the metal disks, while

the larger foreign matter and most of the water settle to

the bottom of the bowl. This matter can be removed

through a drain plug. A ball relief valve in the filter cover

enables the fuel to bypass the filter element if the disks

become clogged. Most types of heavy equipment have

a fuel pressure gauge that indicates when the filters are

dirty.

NOTE: A good practice is to drain about one fourth

of a pint of fuel out of the filter into a container or onto

a rag during the prestart operations. This practice allows

you to drain out any foreign matter that has settled to the

bottom of the filter.

SECONDARY FILTER.— The secondary falter is

usually located between the fuel supply pump and the

fuel injection pump. It contains a fine filter that removes

even the most minute traces of foreign matter from the

1-17

Figure 1-22.-Primary fuel filter.