weighing and marking station. Weighing and marking

procedures are outlined in the Equipment Operator,

Advanced, NAVEDTRA 12537.

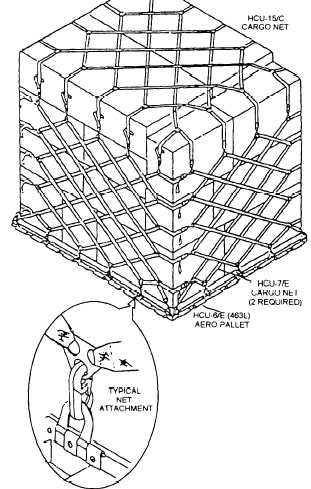

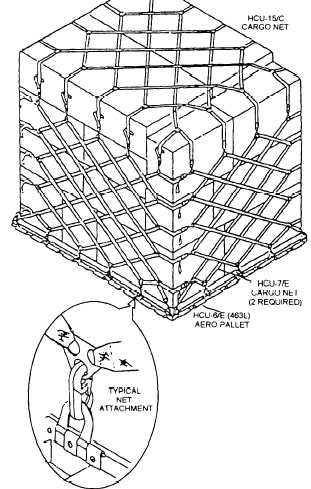

Palletized Cargo

Cargo that is to be loaded on an aircraft is palletized

on 463-L air certified pallets, as shown in figure 6-25.

The weight of an empty 463-L pallet is standardized at

290 pounds; when side and top nets are added the pallet

weight is 355 pounds. These figures are to be used in

weight and balance planning of an aircraft load plan.

The outside dimensions of a 463-L pallet are 88 inches

long and 108 inches wide. The usable space on the pallet

is 84 by 104 inches; this leaves a 9-inch space around

Figure 6-25.-463-L pallet with cargo and net.

6-34

the outside perimeter of the pallet load. Cargo can be

loaded on the pallet up to 96 inches high, and the weight

limitation is 10,000 pounds per pallet maximum.

Each pallet has a total of 22 tie-down rings (six on

the long side and five on the short side) that match up

with the cargo net fasteners. 463-L pallets lock into the

aircraft by a rail on each side of the aircraft.

When loads are placed on a pallet, three point

dunnage must be placed under each pallet. The size of

the dunnage must be at least 4- by 4- by 88-inch timbers.

One timber must be placed under the center of the pallet

and one under each outside edge of the pallet; this helps

prevent warping of the pallets.

To store empty pallets, you should first put down

one set of three point dunnage, then stack the pallets no

more than 10 high. If more pallets must be stacked,

another set of dunnage must be placed on top of the first

10 pallets, then 10 more pallets can be stacked. This

sequence can be repeated up to a maximum of 40 pallets.

Each pallet must be stacked with the cargo loading

surface facing in an upward direction.

During the pallet-building process (placing cargo on

the pallets), always load heavy cargo in the center of the

pallet and build it up with lighter cargo around it. This

will keep the center of balance at the center of the pallet.

All cargo loaded on a 463-L pallet must be placed close

together with no open space between them. If space is

left between cargo items, the cargo may shift on the

pallet during flight and could cause damage to or even

loss of the aircraft.

ADVANCED BASE PLANNING

During World War II when bases were constructed

across the island chains of the Pacific Ocean, it became

apparent that significant savings in both time and

material could be realized if units of materials,

equipment, and personnel required to perform specific

functions were standardized. This was the beginning of

the Advanced Base Functional Components (ABFC)

System that is still in use today. This section will briefly

cover the ABFC System and the Facilities Planning

Guide, NAVFAC P-437.

ADVANCED BASE FUNCTIONAL

COMPONENTS SYSTEM

The Advanced Base Functional Components

System is covered in the Naval Construction Force

(NCF) Manual, NAVFAC P-315, and in volume 2 of the

Facilities Planning Guide, NAVFAC P-437. However,