CHAPTER 3

CHASSIS SYSTEMS

Chassis systems provides operators with a means of

controlling the direction the equipment travels and

allows travel over uneven terrain by controlling the

amount of shock reaching the passengers or cargo. This

chapter covers the basic principles of steering systems,

suspension systems, tires, and brake systems.

STEERING SYSTEMS

Automotive steering mechanisms are classified as

either manual or power. In both types, the arrangement

and function of the linkage are similar. The main

difference is that manual steering requires more effort

for you to steer the vehicle. Some construction

equipment has articulated steering which is powered by

the equipment hydraulic system.

STEERING MECHANISMS

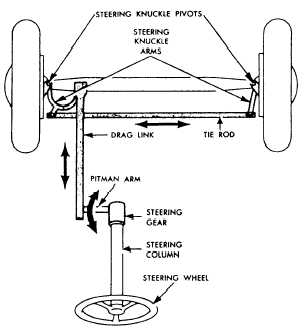

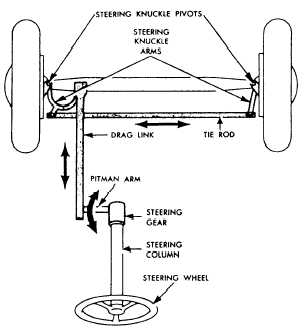

All steering mechanisms have the same basic parts

(fig. 3-1). The steering linkage ties the front wheels

together and connects them to the steering gear case at

Figure 3-1.—Steering linkage assembly.

the lower end of the steering column which, in turn,

connects the gear case to the steering wheel.

The arms and rods of the steering linkage have ball

ends or ball-and-socket ends to provide a swivel

connection between them. These joined ends have

grease fittings, dust seals or boots, and many of them

have end-play adjustment devices. These joints and

devices must be adjusted and lubricated regularly.

The arms, rods, and joints of steering linkage in your

equipment may be arranged differently from those

shown in figure 3-1, but you will find them in the same

general location in the front and underneath the vehicle.

The tie rod is usually behind the axle and keeps the

front wheels in proper alignment. The tie rod is divided

into two lengths and is connected to the steering gear

near the center of the vehicle to provide for easier

steering and maximum leverage.

The drag link between the steering arm and the

pitman arm may be long or short, depending on the

installation.

The pitman arm is splined to the shaft extending

from the steering gear case. It moves in an arc with its

position, depending on which direction the steering

wheel is turned. The arm is vertical when the front

wheels are straight ahead. Therefore, the length of the

drag link is determined by the distance between the

steering arm and the vertical position of the pitman arm.

Unlike the tie rods, the length of the drag link is fixed.

Part of your prestart and operator maintenance

responsibilities is to check and service the steering

linkage lubrication. One example is the connecting

joints between the links that contain bushings.

Additionally, when a vehicle is equipped with manually

operated steering, check the steering gear housing for

lubrication, and, if needed, add the recommended

manufacturer’s gear lubricant. If the vehicle is equipped

with power steering, check the belt tension because

improper tension can cause low oil pressure and hard

steering. Check the fluid level. If the fluid level is low,

add fluid to bring it up to the recommended level and

only use the recommended power steering fluid. Also,

if the level is low, there may be a leak; therefore, check

hose and power steering connections for signs of leaks.

3-1