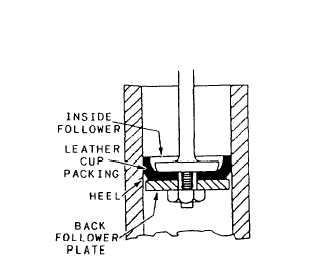

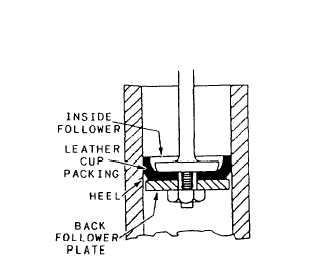

Figure 7-20.–Cup packing.

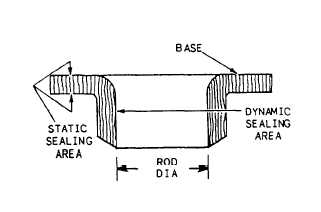

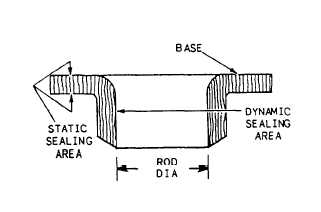

seals. The flange

made of leather,

(sometimes called

fabric-reinforced

the hat) is

rubber, or

homogeneous rubber. Lip sealing occurs only on

the packing ID (fig. 7-21). Flange packings are

generally used only for rod seals when other

packings such as V-rings or U-seals cannot be

used.

DIRT EXCLUSION SEALS

(WIPERS AND SCRAPERS)

Dirt exclusion devices are essential if a

satisfactory life is to be obtained from most rod

seals. The smooth finished moving rod surface,

if not enclosed or protected by some sort of

covering, will accumulate a coating of dust or

abrasive material that will be dragged or carried

into the packing assembly area on the return rod

stroke. Exclusion devices called wipers or scrapers

are designed to remove this coating. While the

terms wiper and scraper are often used

interchangeably, it is useful to reserve scraper

Figure 7-21.—Typical flange packing cross section.

for metal lip-type devices that remove heavily

encrusted deposits of dirt or other abrasive

material that would merely deflect a softer lip and

be carried into the cylinder. Sometimes a rod will

have both a scraper and a wiper, the former to

remove heavy deposits and the latter to exclude

any dust particles that remain. Whenever metallic

scrapers are used with felt wipers in the same

groove, the felt wiper must not be compressed nor

restricted in any way that affects its function as

a lubricator. A wiper installed in a seal assembly

in a pneumatic application may remove too much

oil from the rod, requiring some method of

replacing the oil. A common remedy is to provide

a periodically oiled felt ring between the wiper

and the seal. Felt wipers provide lubrication

to extended operating rods, thus increasing

component wear life. These wipers are only used

to provide lubrication to parts.

Much longer life could be obtained from most

seals if proper attention were given to wipers and

scrapers. Often, wiper or scraper failure is not

noticed when a seal packing fails. As a result, only

the packing is replaced, and the same worn wiper

or scraper is reinstalled to destroy another

packing. Check the wiper or scraper condition

upon its removal. If the wiper is worn, dirty, or

embedded with metallic particles, replace it with

a new one. It is usually good practice to replace

the wiper every time you replace the seal and even

more frequently if the wiper is readily accessible

without component disassembly. If replacements

are not available, wash dirty wipers that are still

in good condition with suitable solvent and

reinstall them. Remember that a wiper or scraper

is deliberately installed as a sacrificial part

to protect and preserve the sealing packing.

Therefore, from a user’s standpoint, wipers and

scrapers should be inspected and replaced as

necessary.

STORAGE OF SEALS

Proper storage practices must be observed to

prevent deformation and deterioration of seals.

Most synthetic rubbers are not damaged by

storage under ideal conditions. However, most

synthetic rubbers will deteriorate when exposed

to heat, light, oil, grease, fuels, solvents, thinners,

moisture, strong drafts, or ozone (form of oxygen

formed from an electrical discharge). Damage by

exposure is magnified when rubber is under

tension, compression, or stress. There are several

7-17