the recommended O-ring entering sleeve (a soft,

thin wall, metallic sleeve) is not available, paper

sleeves and covers may be fabricated by using the

seal package (glossy side out) or lint-free bond

paper (see views B and C of fig. 7-10).

After you place the O-ring in the cavity

provided, gently roll the O-ring with your fingers

to remove any twist that might have occurred

during the installation. After installation, an

O-ring should seat snugly but freely in its groove.

If backup rings are installed in the groove, be

certain the backup rings are installed on the

correct side of the ring.

BACKUP RINGS

Backup rings, also referred to as retainer rings,

antiextrusion devices, and nonextrusion rings, are

washer-like devices that are installed on the

low-pressure side of packing to prevent extrusion

of the packing material. Backup rings in dynamic

seals minimize erosion of the packing materials

and subsequent failure of the seal. At lower

pressures, backup rings will prolong the normal

wear life of the packing. At higher pressures,

backup rings permit greater clearances between

the moving parts. Normally, backup rings are

required for operating pressures over 1500 psi.

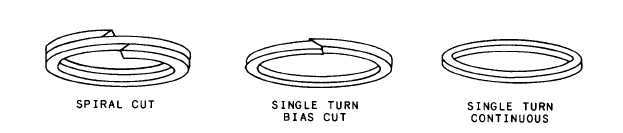

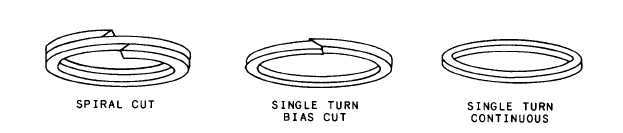

Backup rings can be made of polytetra-

fluoroethylene, hard rubber, leather, and other

materials. The most common material currently

used is tetrafluoroethylene (TFE). Backup rings

are available as single-turn continuous (uncut or

solid), single-turn (bias) cut, and spiral cut. See

figure 7-11. Leather rings are always furnished in

solid ring form (unsplit). Rings of TFE are

available in all three types.

Packaging and Storing

Backup rings are not color-coded or otherwise

marked and must be identified from the packaging

labels. The dash number following the military

standard number found on the package indicates

the size, and usually relates directly to the dash

number of the O-rings for which the backup ring

is dimensionally suited. Backup rings made of

TFE do not deteriorate with age and do not have

shelf life limitations. TFE backup rings are

provided by manufacturer either in individually

sealed packages or on mandrels. If unpackaged

rings are stored for a long time without the use

of mandrels, a condition of overlap may develop.

Overlap occurs when the ID of the backup ring

becomes smaller and its ends overlap each other.

To correct this overlap condition, stack TFE rings

on a mandrel of the correct diameter, and clamp

the rings with their coils flat and parallel. Place

the rings in an oven at a maximum temperature

of 1770C (3500F) for approximately 10 minutes.

Do not overheat them because fumes from

decomposing TFE are toxic. Remove and

water-quench the rings. Store the rings at room

temperature before you use them (preferably for

48 hours).

Installation

Care must be taken in handling and installing

backup rings. Do not insert them with sharp

tools. Backup rings must be inspected prior

to using them for evidence of compression

damage, scratches, cuts, nicks, or frayed con-

ditions. If O-rings are to be replaced where

backup rings are installed in the same groove,

never replace the O-ring without replacing

the backup rings, or vice versa. Many seals

use two backup rings, one on either side of the

O-ring (fig. 7-12). Two backup rings are used

primarily in situations (such as a reciprocating

piston seal) where alternating pressure direction

can cause packing to be extruded on both sides

of the gland.

Figure 7-11.—Types of backup rings.

7-12