mandatory. Ensure that the area used for such

installations is clean and free from all

contamination.

Remove each O-ring that is to be installed

from its sealed package and inspect it for defects

such as blemishes, abrasions, cuts, or punctures.

Although an O-ring may appear perfect at first

glance, slight surface flaws may exist. These are

often capable of preventing satisfactory O-ring

performance. O-rings should be rejected for flaws

that will affect their performance.

By rolling the ring on an inspection cone or

dowel, the inner diameter surface can be checked

for small cracks, particles of foreign material, and

other irregularities that will cause leakage or

shorten its life. The slight stretching of the ring

when it is rolled inside out will help to reveal some

defects not otherwise visible. A further check of

each O-ring should be made by stretching it

between the fingers, but care must be taken not to

exceed the elastic limits of the rubber. Following

these inspection practices will prove to be a

maintenance economy. It is far more desirable to

take care identifying and inspecting O-rings than to

repeatedly overhaul components with faulty seals.

After inspection and prior to installation,

lubricate the O-ring, and all the surfaces that it

must slide over with a light coat of the system fluid

or a lubricant approved for use in the system.

Consult the applicable technical instruction or

Naval Ships’ Technical Manual for the correct

lubricant for pneumatic systems.

Assembly must be made with care so that the

O-ring is properly placed in the groove and not

damaged as the gland is closed. During some

installations, such as on a piston, it will be

necessary to stretch the O-ring. Stretch the O-ring

as little and as uniformly as possible. Avoid rolling

or twisting the O-ring when maneuvering it into

place. Keep the position of the O-ring mold line

constant. O-rings should not be left in a twisted

condition after installation.

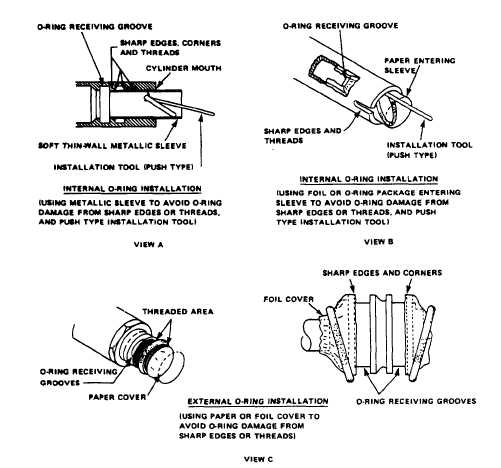

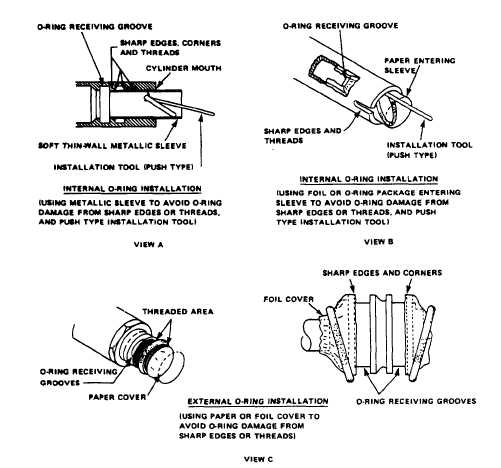

If the O-ring installation requires spanning or

inserting through sharp-threaded areas, ridges,

slots, and edges, use protective measures, such as

the O-ring entering sleeve (fig. 7-10, view A). If

Figure 7-10.–O-ring installation.

7-11