packing stack, is flat on one side and V-shaped

on the other to properly support the adjacent

V-ring. Proper design and installation of the

female adapter has significant impact on the

service life and performance of the V-rings

because the female adapter bridges the clearance

gap between the moving surfaces and resists

extrusion.

The packing set is installed in a cavity that is

slightly deeper than the free stack height (the

nominal overall height of a V-ring packing set,

including the male and female adapters as

measured before installation) and as wide as the

nominal cross section of the V-rings. This cavity,

called a packing gland or stuffing box, contains

and supports the packing around the shaft, rod,

or piston. Adjustment of the packing gland depth

through the use of shims or spacers is usually

necessary to obtain the correct squeeze or

clearance on the packing stack for good service

life.

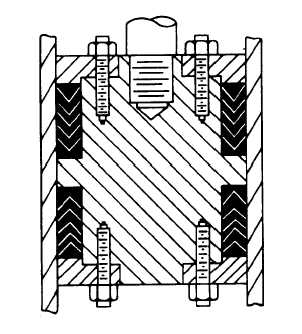

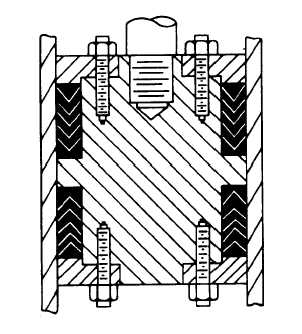

Two basic installations apply to V-ring

packings. The more common is referred to as an

outside packed installation, in which the packing

seals against a shaft or rod, as shown in figure

7-4. The inside packed installation, is shown as

a piston seal in figure 7-5. When V-ring packing

is to be used in an inside packed installation, only

endless ring packing should be used. Where

pressures exist in both directions, as on a

double-acting piston, opposing sets of packing

Figure 7-5.—Inside packed V-ring installation.

should always be installed so the sealing lips face

away from each other as in figure 7-5. This

prevents trapping pressure between the sets of

packings. The female adapters in inside packed

installations should always be located adjacent to

a fixed or rigid part of the piston.

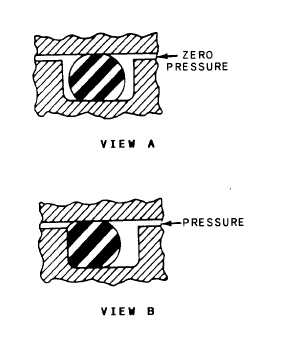

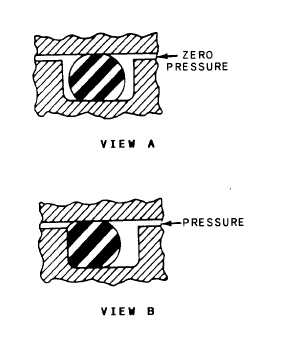

O-RINGS

An O-ring is doughnut-shaped. O-rings are

usually molded from rubber compounds; how-

ever, they can be molded or machined from plastic

materials. The O-ring is usually fitted into a

rectangular groove (usually called a gland)

machined into the mechanism to be sealed. An

O-ring seal consists of an O-ring mounted

in the gland so that the O-ring’s cross section

is compressed (squeezed) when the gland is

assembled (fig. 7-6).

An O-ring sealing system is often one of the

first sealing systems considered when a fluid

closure is designed because of the following

advantages of such a system:

1.

2.

3.

4.

5.

6.

7.

Simplicity

Ruggedness

Low cost

Ease of installation

Ease of maintenance

No adjustment required

No critical torque in clamping

Figure 7-6.—O-ring installed in a gland.

7-6