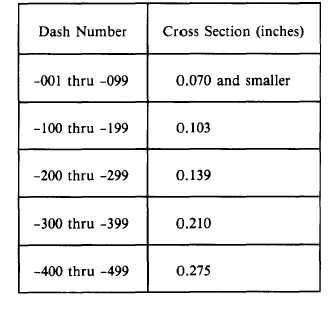

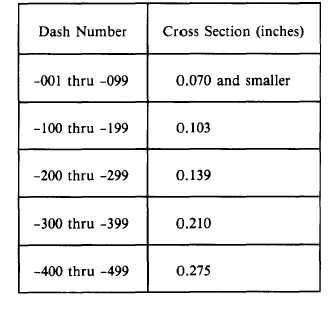

Sizes

A standardized dash number system for

O-ring sizes is used in many military and industrial

specifications. The O-ring size is identified by a

dash number rather than the actual dimensions

for convenience. The basis for the dash numbers

is contained in Aerospace Standard AS568. For

nongasket O-rings (packing), the dash numbers

are divided into groups of one hundred. Each

hundred group identifies the cross section size of

the O-rings within the group (table 7-2).

The 900 series dash numbers contained in

AS568 identify all the presently standardized

straight thread tube fitting boss gaskets. With the

exception of -901, the last two digits of the dash

designate the tube size in 16ths of an inch. For

example, the -904 size is for a 1/4-inch tube.

Dimensions

The critical dimensions of an O-ring are its ID,

its cross sectional diameter (W), and the height

and width of the residual molding flash (see

fig. 7-7).

Nominal dimensions have been used to

describe O-ring sizes, although this practice is

rapidly being replaced by the use of dash numbers.

The actual inside diameter of a seal will be slightly

less than the nominal ID, but the actual OD will

Table 7-2.—O-Ring Dash Numbers Versus Cross Section

Sizes

be slightly larger than the nominal OD. For

example, an AS568-429 O-ring is described in

nominal dimensions as 5 inches ID by 5-1/2 inches

OD by 1/4-inch W. Actual dimensions are 4.975

inches ID by 5.525 inches OD by 0.275 inches W.

Specifications

Material and performance requirements

for O-rings are often identified in military

specifications. The dimensions of these O-rings

will usually be found in accompanying slash sheets

(which bear the specification number and are a

part of the specification) or will be identified by

various drawings and standards that relate to the

specification. Included among the specifications

are Air Force-Navy Standards (AN), Mili-

tary Standards (MS), and National Aerospace

Standards (NAS). If the specification does not

identify sizes, the sizes should be identified by the

AS568 dash number. Usually, you can use

drawings, technical manuals, and allowance parts

lists (APLs) to identify replacement O-rings.

(Notes 2 and 3 of table 7-1 list some of the

frequently used military specifications).

Cure Date

A cure date is as applicable to natural or

synthetic O-rings as it is to rubber hoses. This date

is the basis for determining the age of O-rings.

It is extremely important that the cure date be

noted on all packages.

Shelf Life and Expiration Date

All elastomers change gradually with age;

some change more rapidly than others. The

shelf life for rubber products is contained in

MIL-HDBK-695.

Check the age of natural or synthetic rubber

preformed packings before installation to

determine whether they are acceptable for use.

Make a positive identification, indicating the

source, cure date, and expiration date. Ensure that

this information is available for all packing used.

Shelf life requirements do not apply once the

packing is installed in a component.

The expiration date is the date after which

packing should not be installed. The expiration

date of all packings can be determined by adding

the shelf life to the cure date.

7-8