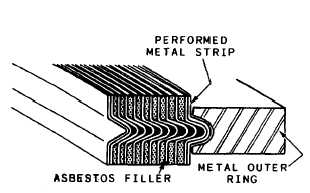

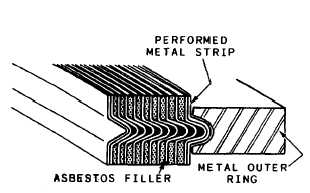

Figure 7-1.—Spiral-wouna metallic-asbestos gasket.

easily bent and requires careful handling. In

addition, copper becomes hard when used over

long periods and when subjected to compression.

Whenever a unit or component is disassembled,

the copper sealing rings should be replaced.

However, if new rings are not available and the

part must be repaired, the old ring should be

softened by annealing. (Annealing is the process

of heating a metal, then cooling it, to make it

more pliable and less brittle.)

Metallic piston rings are used as packing in

some fluid power actuating cylinders. These rings

are similar in design to the piston rings in

automobile engines.

Metal is also used with asbestos to form

spiral-wound metallic-asbestos gaskets (fig. 7-1).

These gaskets are composed of interlocked plies

of preformed corrugated metal and asbestos

strips, called a filler.

The filler may or may not be encased in a solid

metal outer ring. These gaskets are used in flanged

connections and for connecting the body to the

bonnet in some valves, and are usually required

in specific high-pressure, high-temperature

applications.

RUBBER

The term rubber

and synthetic rubbers,

covers many natural

each of which can be

compounded into numerous varieties. The

characteristics of these varieties have a wide range,

as shown in table 7-1. The table shows, with the

exception of a few basic similarities, that rubbers

have diverse properties and limitations; therefore,

specific applications require careful study before

the sealing material is selected.

Natural rubbers have many of the charac-

teristics required in an effective seal. However,

their very poor resistance to petroleum fluids and

rapid aging when exposed to oxygen or ozone limit

their use. Today their use has almost ceased.

There are two general classes of synthetic

rubber seals. One class is made entirely of a certain

synthetic rubber. The term homogeneous, which

means having uniform structure or composition

throughout, is frequently used to describe this

class of seal. The other class of seal is made by

impregnating woven cotton duck or fine-weave

asbestos with synthetic rubber. This class is

sometimes referred to as fabricated seals.

Additional information on sealing materials

is provided in the Military Handbook, Gasket

Materials (Nonmetalic), MIL-HDBK-212; and

the Naval Ships’ Technical Manual, chapter 078.

TYPES OF SEALS

Fluid power seals are usually typed according

to their shape or design. These types include

T-seals, V-rings, O-rings, U-cups and so on. Some

of the most commonly used seals are discussed

in the remainder of this chapter.

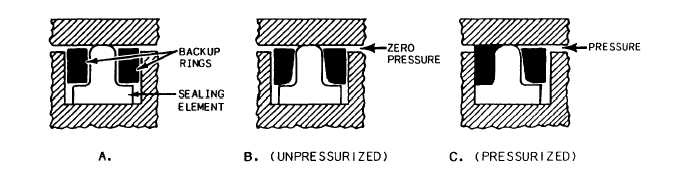

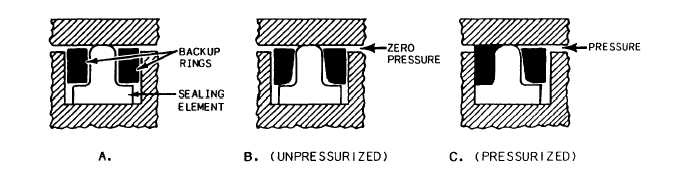

T-SEALS

The T-seal has an elastomeric bidirectional

sealing element resembling an inverted letter T.

This sealing element is always paired with two

special extrusion-resisting backup rings, one on

each side of the T. The basic T-seal configuration

is shown in figure 7-2, view A. The backup rings

Figure7 - 2 . – T - seals .

7-3