return/exhaust (R), and two cylinder ports (C/1

and C2). A hollow sleeve fits into the main bore

of the body. There are O-rings placed at intervals

around the outside diameter of the sleeve. These

O-rings form a seal between the sleeve and the

body, creating chambers around the sleeve. Each

of the chambers is lined up with one of the fluid

ports in the body. The drilled passage in the body

accounts for a fifth chamber which results in

having the two outboard chambers connected to

the return/exhaust port. The sleeve has a pattern

of holes drilled through it to allow fluid to flow

from one port to another. A series of holes are

drilled into the hollow center sleeve in each

chamber.

The sleeve is prevented from turning by a

sleeve retainer bolt or pin which secures it to the

valve body.

The sliding spool fits into the hollow center

sleeve. This spool is similar to the spool in the

two-way valve, except that this spool has three

pistons or lands. These lands are lapped or

machine fitted to the inside of the sleeve.

One end of the sliding spool is connected to

a handle either directly or by mechanical linkage

to a more desirable location. When the control

handle is moved, it will position the spool within

the sleeve. The lands of the spool then line up

different combinations of fluid ports thus

directing a flow of fluid through the valve.

The detent spring is a clothespin-type spring,

secured to the end of the body by a spring

retaining bolt. The two legs of the spring extend

down through slots in the sleeve and fit into the

detents. The spool is gripped between the two legs

of the spring. To move the spool, enough force

must be applied to spread the two spring legs and

allow them to snap back into the next detent,

which would be for another position.

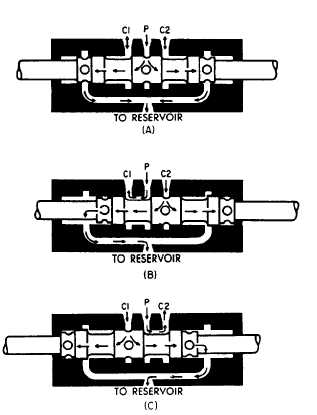

Figure 6-34, view A, shows a manually

operated sliding spool valve in the neutral

position. The detent spring is in the center detent

of the sliding spool. The center land is lined up

with the pressure port (P) preventing fluid from

flowing into the valve through this port. The

return/exhaust port is also blocked, preventing

flow through that port. With both the pressure

and return ports blocked, fluid in the actuating

lines is trapped. For this reason, a relief valve is

usually installed in each actuating line when this

type of valve is used.

Figure 6-34, view B, shows the valve in the

working position with the end of the sliding spool

retracted. The detent spring is in the outboard

detent, locking the sliding spool in this position.

The lands have shifted inside the sleeve, and the

ports are opened. Fluid under pressure enters the

sleeve, passes through it by way of the drilled

holes, and leaves through cylinder port C2. Return

fluid, flowing from the actuator enters port C1,

flows through the sleeve, and is directed out the

return port back to the reservoir or exhausted to

the atmosphere. Fluid cannot flow past the spool

lands because of the lapped surfaces.

Figure 6-34, view C, shows the valve in the

opposite working position with the sliding spool

extended. The detent spring is in the inboard

detent. The center land of the sliding spool is now

on the other side of the pressure port, and the

fluid under pressure is directed through the sleeve

and out port C1. Return fluid flowing in the other

cylinder port is directed to the drilled passage in

the body. It flows along this passage to the other

end of the sleeve where it is directed out of the

return/exhaust port.

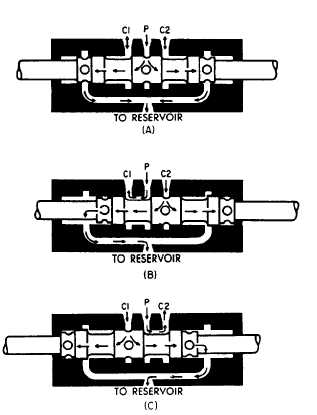

The directional control valves previously

discussed are for use in closed-center fluid power

systems. Figure 6-35 shows the operation of

Figure 6-35.—Open center, sliding spool directional control

valve.

6-24