forces set up within the cylinder, since the forces

there are equal. As indicated by the arrows against

the pistons of the spool, the same pressure acts

on equal areas on their inside surfaces. In the

closed position, one of the pistons of the spool

simply blocks the inlet port, thus preventing flow

through the valve.

A number of features common to most sliding

spool valves are shown in figure 6-23. The small

ports at either end of the valve housing provide

a path for any fluid that leaks past the spool to

flow to the reservoir. This prevents pressure from

building up against the ends of the pistons, which

would hinder the movement of the spool. When

spool valves become worn, they may lose balance

because of greater leakage on one side of the spool

than on the other. In that event, the spool would

tend to stick when it is moved back and forth.

Small grooves are therefore machined around the

sliding surface of the piston; and in hydraulic

valves, leaking liquid will encircle the pistons and

keep the contacting surfaces lubricated and

centered.

THREE-WAY VALVES

Three-way valves contain a pressure port, a

cylinder port, and a return or exhaust port. The

three-way directional control valve is designed to

operate an actuating unit in one direction; it

permits either the load on the actuating unit or

a spring to return the unit to its original position.

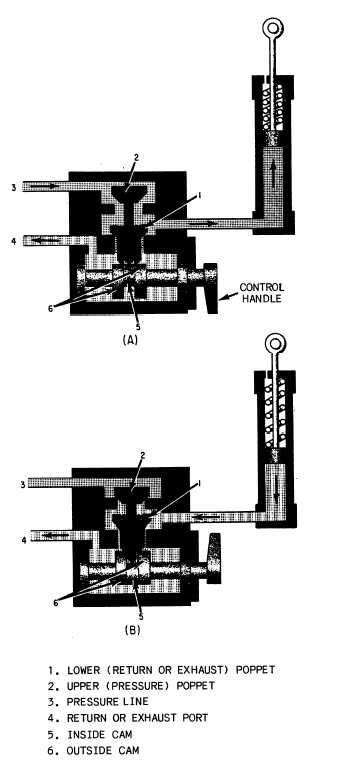

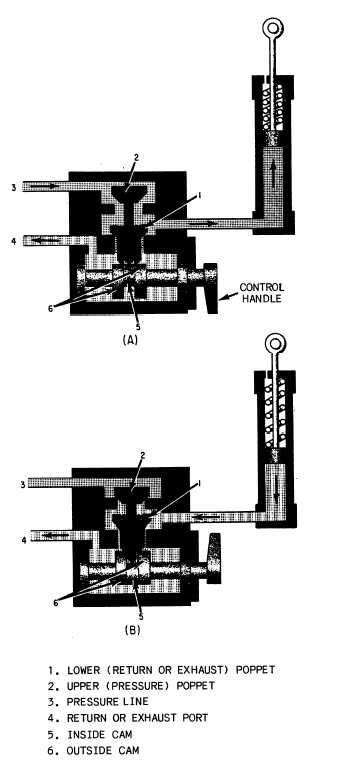

Cam-Operated Three-Way Valves

Figure 6-28 shows the operation of a cam-

operated, three-way, poppet-type directional

control valve. View A shows fluid under pressure

forcing the piston outward against a load. The

upper poppet (2) is unseated by the inside cam

(5), permitting fluid to flow from the line (3) into

the cylinder to actuate the piston. The lower

poppet (1) is seated, sealing off the flow into the

return line (4). As the force of the pressurized fluid

extends the piston rod, it also compresses the

spring in the cylinder.

View B shows the valve with the control

handle turned to the opposite position. In this

position, the upper poppet (2) is seated, blocking

the flow of fluid from the pressure line (3). The

lower poppet (1) is unseated by the outside cam

(6). This releases the pressure in the cylinder and

allows the spring to expand, which forces the

piston rod to retract. The fluid from the cylinder

flows through the control valve and out the return

Figure 6-28.—Three-way, poppet-type directional control

valve (cam-operated).

6-19