the lobes, which unseat one pressure poppet and

one return/exhaust poppet (fig. 6-31). The valve

is now in the working position. Fluid under

pressure, entering the pressure port, flows through

the vertical fluid passages in both pressure poppets

seats. Since only one pressure poppet, IN (2), is

unseated by the cam lobe, the fluid flows past the

open poppet to the inside of the poppet seat. From

there it flows through the diagonal passages, out

one cylinder port, C2, and to the actuating unit.

Return fluid from the actuating unit enters the

other cylinder port, C1. It then flows through the

corresponding fluid passage, past the unseated

return poppet, OUT (1), through the vertical fluid

passages, and out the return/exhaust port. When

the camshaft is rotated in the opposite direction

to the neutral position, the two poppets seat and

the flow stops. When the camshaft is further

rotated in this direction until the stop pins hits,

the opposite pressure and return poppets are

unseated. This reverses the flow in the working

lines, causing the actuating unit to move in the

opposite direction.

Rotary Spool Valve

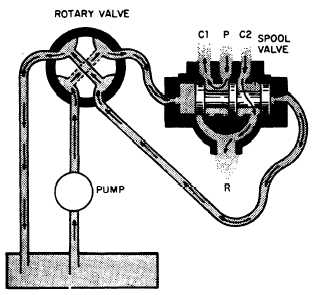

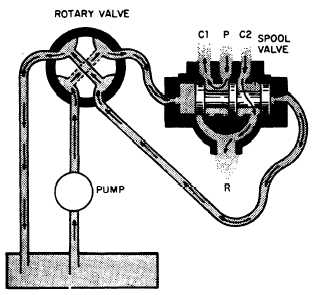

Four-way directional control valves of this

type are frequently used as pilot valves to direct

flow to and from other valves (fig. 6-32). Fluid

is directed from one source of supply through the

rotary valve to another directional control valve,

where it positions the valve to direct flow from

another source to one side of an actuating unit.

Fluid from the other end of the main valve flows

through a return line, through the rotary valve

to the return or exhaust port.

The principal parts of a rotary spool direc-

tional control valve are shown in figure 6-22.

Figure 6-31.—Working view of a poppet-type, four-way

directional control valve.

Figure 6-32.—Sliding spool valve controlled by a rotary spool

valve.

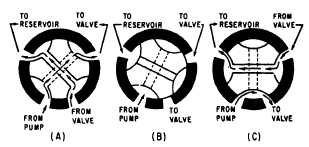

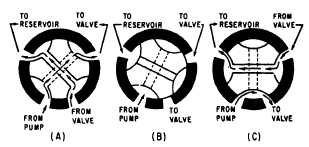

Figure 6-33 shows the operation of a rotary spool

valve. Views A and C show the valve in a position

to deliver fluid to another valve, while view B

shows the valve in the neutral position, with all

passages through the valve blocked.

Rotary spool valves can be operated manually,

electrically, or by fluid pressure.

Sliding Spool Valve

The sliding spool four-way directional control

valve is similar in operation to the two-way

valve previously described in this chapter. It is

simple in its principle of operation and is the

most durable and trouble-free of all four-way

directional control valves.

The valve described in the following para-

graphs is a manually operated type. The same

principle is used in many remotely controlled

directional control valves.

The valve (fig. 6-34) consists of a valve body

containing four fluid ports—pressure (P),

Figure 6-33.—Operation of a rotary spool, four-way

directional control valve.

6-22