figure 7-9. These tools should be fabricated from

soft metal such as brass or aluminum; however,

tools made from phenolic rod, wood, or plastic

may also be used.

Tool surfaces must be well rounded, polished,

and free of burrs. Check the tools often, especially

the surfaces that come in contact with O-ring

grooves and critical polished surfaces.

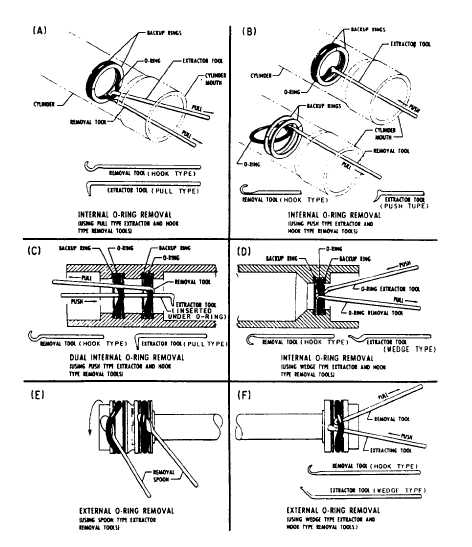

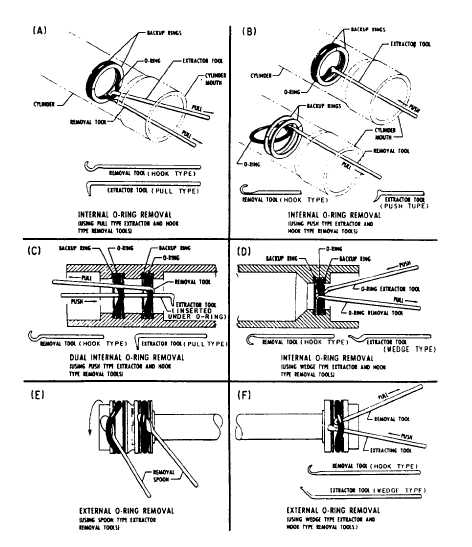

Notice in figure 7-9, view A, how the

hook-type removal tool is positioned under the

O-ring and then lifted to allow the extractor tool,

as well as the removal tool, to pull the O-ring from

its cavity. View B shows the use of another type

of extractor tool in the removal of internally

installed O-rings.

In view C, notice the extractor tool positioned

under both O-rings at the same time. This method

of manipulating the tool positions both O-rings,

which allows the hook-type removal tool to

extract both O-rings with minimum effort. View

D shows practically the same removal as view C,

except for the use of a different type of extractor

tool.

The removal of external O-rings is less difficult

than the removal of internally installed O-rings.

Views E and F show the use of a spoon-type

extractor, which is positioned under the seal. After

the O-ring is dislodged from its cavity, the

spoon is held stationary while the piston is

simultaneously rotated and withdrawn. View F

is similar to view E, except that only one O-ring

is installed, and a different type of extractor tool

is used. The wedge-type extractor tool is inserted

beneath the O-ring; the hook-type removal tool

hooks the O-ring. A slight pull on the latter tool

removes the O-ring from its cavity.

After removing all O-rings, cleaning of the

affected parts that will receive new O-rings is

Figure 7-9.—O-ring tools and O-ring removal.

7-10