After proper arrangement, use some system of

Methods of Applying Glue

marking the pieces of stock. This is so they will not

be disarranged during the gluing-up process. Apply

When you need thicker or wider material but it

is not available, you will have to glue several pieces

a good coat of glue to the surface of the piece of

stock lying face up. Place one of the other pieces of

of material together. The two principal methods

stock face-to-face with the glued surface. Rub back

used for gluing wood stock are face-to-face gluing

and forth or in a circular motion. Exert as much

and edge-to-edge gluing.

down pressure as possible. This spreads the glue

evenly throughout the joint and helps prevent air

In face-to-face gluing, first determine the sizes

bubbles. In addition, a certain amount of glue is

of stock needed. Then, you should decide what

driven into the pores of the wood. The glued

available stock can be glued up to produce the

surfaces are pulled closer together. Repeat the

required size. Remove enough lumber from the

rack to do the job. Saw the lumber to the required

preceding gluing operations until all pieces are

lengths. Dress one face and one edge of each piece

assembled

of material on the jointer. Dress the material to the

proper thickness in the planer. Rip the pieces to

Position clamps and tighten glued-up stock as

the proper width in the circular saw. Adjust the

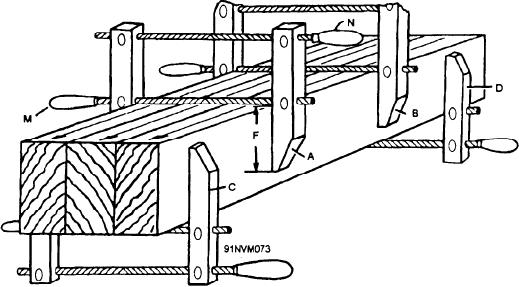

shown in figure 3-47. Place clamp A in a position

hand clamps to an approximate jaw opening. Lay

so that when the clamps are all in place, the space

the stock on the bench and fit each clamp loosely

between them will be somewhat equal throughout

over the stock. Then place them in a spot where

the length of the material. Keep lower clamp

they can be easily reached.

spindle M at least 1/2 inch above the surface of the

material. Tighten up on spindle M and release

Place the stock in the desired gluing position.

spindle N until a fair amount of pressure is on that

Alternate in relation to the growth rings. The

part of the jaws near M. Next, turn spindles M and

warpage of each piece offsets the warpage of the

N until the entire face of jaw F is exerting an even

one next to it if this arrangement is followed. Also,

pressure on the face of the material. Use enough

arrange the pieces so the grain of their respective

force to squeeze excess glue from the joints of the

surfaces runs in the same direction. Otherwise,

glued-up stock and draw all surfaces tightly together.

difficulties may arise later when dressing the job to

proper thickness. Planing with the grain on one

Adjust and tighten clamp B just like clamp A.

part of the surface may prove to be the wrong

As each clamp is added, the glue is forced along, as

direction for an adjacent area.

well as out of, the joint. If the ends are clamped

first, a large amount of glue is trapped in the

Figure 3-47.--Face-to-face gluing.

3-31