nominal pipe size of 3 inches has an actual measured

DIA

Wall

ID

Schedule

OD

OD of 3.50 inches. A pipe with a nominal pipe size

4

40

4.500

4.026

0.237

(NPS) of 2 inches has an actual measured OD of 2.375

inches. For pipe that is 12 inches or larger, the NPS and

4

80

4.500

3.826

0.337

the actual measured OD are the same. For example, a

pipe with an NPS of 14 inches has an actual measured

120

4

4.500

0.438

3.624

OD of 14 inches. Nominal dimensions are used to

simplify the standardization of pipe fittings and pipe

4

160

4.500

0.531

3.438

taps and threading dies.

Therefore, you can use a pipe schedule to select

The wall thickness of pipe is identified by reference

either a greater or smaller pipe thickness depending on

to wall thickness schedules established by the American

the requirements of the job.

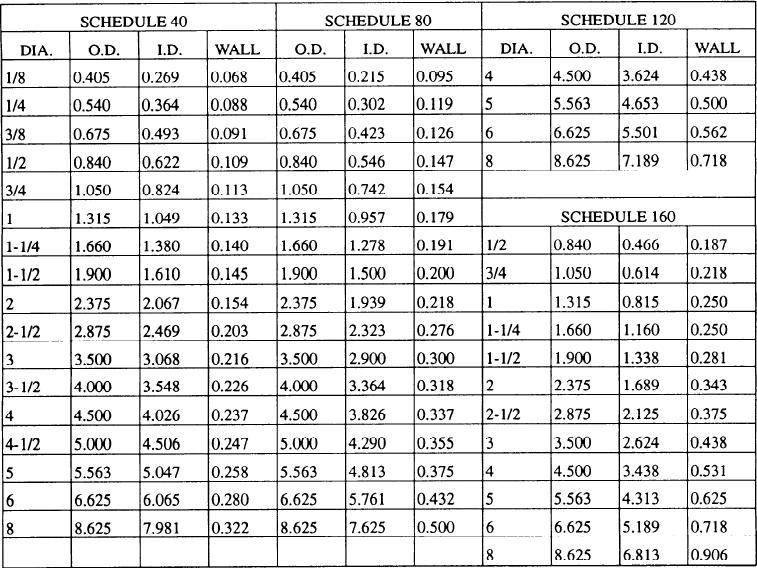

Standards Association. As an example, table 15-1

shows four schedules: 40, 80, 120, and 160. Each of

You may have seen pipe identified as STANDARD

these schedules shows a different wall thickness and,

(Std), EXTRA STRONG (XS), and DOUBLE EXTRA

therefore, a different ID for any given NPS.

STRONG (XXS). These designations also refer to wall

thickness. Figure 15-1 shows the relative wall

Assume that you have a pipe with a nominal size of

thickness of pipes having the same NPS (OD). Note

4 inches. Using table 15-1, you can see that a 4-inch

that the ID is reduced as the wall thickness is increased.

pipe can have the following ID and OD dimensions.

Pipe is manufactured in a number of different wall

Table 15-1.--Schedule Designations of Pipe Size

15-2