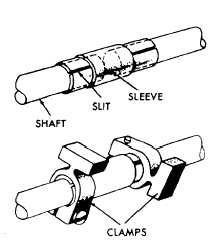

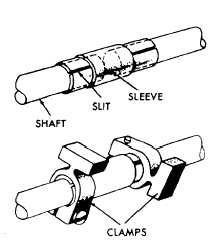

Figure 11-15.-Sleeve coupling.

pivot, and the two links connect at two points in different

directions from the pivot. By properly locating the

connection points, the output links can move in any

desired direction.

All linkages require occasional adjustments or

repair, particularly when they become worn. To make

the proper adjustments, a person must be familiar with

the basic parts that constitute a linkage. Adjustments are

normally made by lengthening or shortening the rods

and shafts by a clevis or turnbuckle.

COUPLINGS

The term coupling applies to any device that holds

two parts together. Line shafts that make up several

shafts of different lengths may be held together by any

of several types of shaft couplings.

SLEEVE COUPLING

You may use the sleeve coupling (fig. 11-15) when

shafts are closely aligned. It consists of a metal tube slit

at each end. The slitted ends enable the clamps to fasten

the sleeve securely to the shaft ends. With the clamps

tightened, the shafts are held firmly together and turn as

one shaft. The sleeve coupling also serves as a

convenient device for making adjustments between

units. The weight at the opposite end of the clamp from

the screw merely offsets the weight of the screw and

clamp arms. Distributing the weight evenly reduces the

shaft vibration.

OLDHAM COUPLING

The Oldham coupling, named for its inventor,

transmits rotary motion between shafts that are parallel

but not always in perfect alignment.

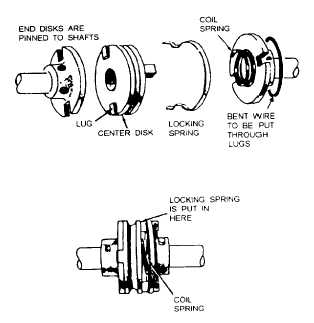

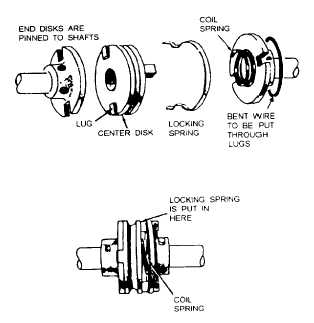

Figure 11-16.-Oldham coupling.

An Oldham coupling (fig. 11-16) consists of a pair

of disks, one flat and the other hollow. These disks are

pinned to the ends of the shafts. A third (center) disk,

with a pair of lugs projecting from each face of the disk,

fits into the slots between the two end disks and enables

one shaft to drive the other shaft. A coil spring, housed

within the center of the hollow end disk, forces the

center disk against the flat disk. When the coupling is

assembled on the shaft ends, a flat lock spring is slipped

into the space around the coil spring. The ends of the flat

spring are formed so that when they are pushed into the

proper place, the ends of the spring push out and lock

around the lugs. A lock wire is passed between the holes

drilled through the projecting lugs to guard the

assembly. The coil spring compensates for any change

in shaft length. (Changes in temperature may cause the

shaft length to vary.)

The disks, or rings, connecting the shafts allow a

small amount of radial play. This play allows a small

amount of misalignment of the shafts as they rotate. You

can easily connect and disconnect the Oldham type

couplings to realign the shafts.

OTHER TYPES OF COUPLINGS

We use four other types of couplings extensively in

naval equipment:

1. The fixed (sliding lug) coupling, which is

nonadjustable; it does allow for a small amount of

misalignment in shafting (fig. 11-17).

2. The flexible coupling (fig. 11-18), which

connects two shafts by a metal disk. Two coupling hubs,

11-10