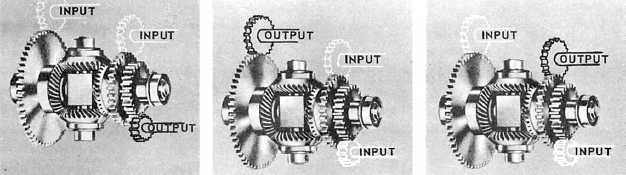

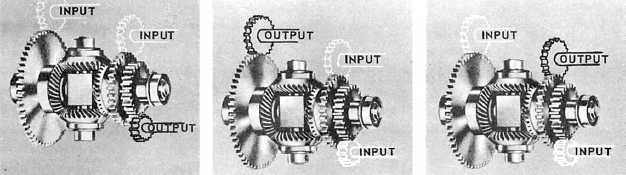

Figure 11-13.—Differential gear hookups.

will be equal to half the difference between the

revolutions of the two inputs. A change in the gear

ratio to the output shaft can then give us any

proportional answer we wish.

We have been describing a hookup wherein the

two sides are inputs and the spider shaft is the

output. As long as you recognize that the spider

follows the end gears for half the sum, or

difference, of their revolutions, you don’t need to

use this type of hookup. You may use the spider

shaft as one input and either of the sides as the

other. The other side will then become the output.

Therefore, you may use three different hookups

for any given differential, depending on which is

the most convenient mechanically, as shown in

figure 11-13.

In chapter 13 of this book, we will describe the

use of the differential gear in the automobile.

Although this differential is similar in principle,

you will see that it is somewhat different in its

mechanical makeup.

LINKAGES

A linkage may consist of either one or a

combination of the following basic parts:

1. Rod, shaft, or plunger

2. Lever

3. Rocker arm

4. Bell crank

These parts combined will transmit limited

rotary or linear motion. To change the direction of

a motion, we use cams with the linkage.

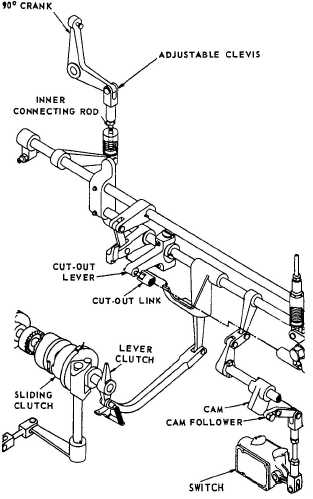

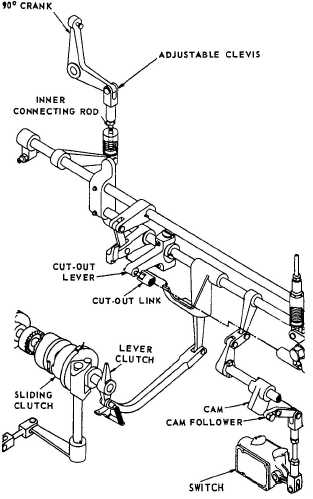

Lever-type linkages (fig. 11-14) are used in

equipment that you open and close; for instance,

valves in electric-hydraulic systems, gates

clutches, and clutch-solenoid interlocks. Rocker

arms are merely a variation, or special use, of

levers.

Bell cranks primarily transmit motion from

a link traveling in one direction to

another link moving in a different direction.

The bell crank mounts on a fixed

Figure 11-14.—Linkages.

11-9