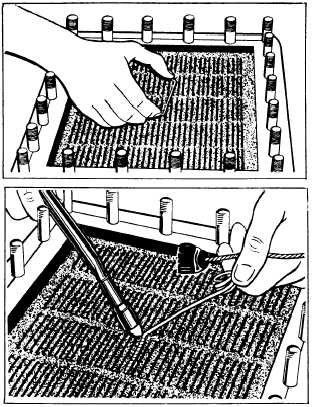

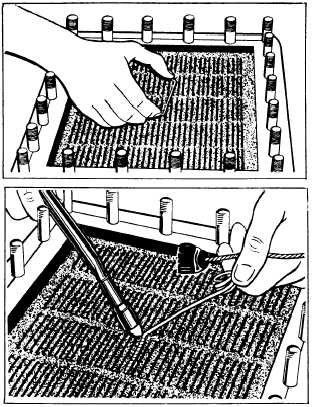

121.33

Figure 3-13.—Emergency repair of a tube leak in a radiator

type heat exchanger.

should be replaced as soon as a leak develops, if

a replacement is available. The presence of one

leak, unless caused by dropping or accidental

puncture, indicates that other areas in the heat

exchanger may be eroded.

In shell-and-tube heat exchangers, a leaking

tube must be replaced as soon as possible. In an

emergency, a faulty tube may be blocked off by

inserting a special plug at each end, until the tube

can be replaced. An air lance or water lance

should be used to clean the tubes of a shell-and-

tube heat exchanger. If the scale has hardened in

the tubes, a round bristle brush or soft rubber

plugs may be used to clean the tubes. When clean-

ing the tubes by mechanical means, avoid

damaging the protective coating inside the tubes.

These tubes should never be polished, as the tar-

nish on the tubes acts as insulation to prevent

Chapter 3—ENGINE MAINTENANCE

further corrosion. Removing the tarnish will also

reduce the tube wall thickness and over a period

of time and a number of cleanings, could suffi-

ciently reduce tube strength, resulting in tube

failure. For the proper procedures for cleaning

shell and tube type heat exchangers and the

safety precautions, use the PMS maintenance

requirements cards, the manufacturer’s technical

manual and Naval Ships’s Technical Manual,

chapter 254.

LUBRICATING SYSTEM

To ensure that all the parts of an engine receive

adequate lubrication, it is essential that all parts

of the lubricating oil system be properly main-

tained at all times. Some parts which may be a

source of trouble are considered in this section.

For other information on lubricating systems, see

Engineman 3 & 2, NAVEDTRA 10541 (current

edition).

LUBE OIL PUMPS

Pumps used in engine lubricating systems are

of the positive displacement type. In some pumps

pressure control is maintained by pressure

regulating or pressure relief valves built directly

into the pump; in other pumps, valves exterior

to the pump are used for this purpose. Most

regulating devices recirculate excess lube oil back

to the suction side of the pump, but some pumps

discharge excess oil directly into the engine sump.

Pump casualties, as well as many other lube

systems failures, are indicated by the loss of lube

oil pressure. The loss of oil pressure can be

recognized by checking the pressure gages at

prescribed intervals, or by means of an electrical

alarm system. Most lube oil pump failures are

generally due to wear, and develop gradually.

Failures may also occur abruptly if a drive shaft

breaks, or some parts suffer physical deforma-

tion. Such failures are usually indicated by ab-

normal noise in the pump and by sounding of the

low-pressure lube oil alarm.

The warning system should be tested at

specified intervals, usually when an engine is

being started or secured. Warning systems do not

excuse personnel from their responsibility for

keeping a vigilant and accurate watch on engine

3-15