position, the dial will be upside down, making it

necessary to use a mirror and flashlight to obtain a

reading.

NOTE: Once you have placed the indicator in

position for the first deflection reading, do not touch the

gauge until you have taken and recorded all four

readings.

Deflection readings are also used to determine

correct alignment between the engine and the generator

or between the engine and the coupling. However, when

determining alignment, you should take a set of

deflection readings at the crank nearest the generator or

the coupling. In aligning an engine and generator, you

may need to install new chocks between the generator

and its base to bring the deflection within the allowable

value. You may also need to shift the generator

horizontally to obtain proper alignment. To align an

engine and a coupling, first, correctly align the coupling

with the drive shaft; then, properly align the engine to

the coupling, rather than aligning the coupling to the

engine.

BEARING TROUBLES

Bearings become a continual source of trouble

unless personnel entrusted with operating the engine

follow the recommended operation and maintenance

procedures exactly.

Severe bearing failures are indicated during engine

operation by a pounding noise or by the presence of

smoke in the vicinity of the crankcase. Impending

failures may sometimes be identified by a rise in the

lubricating oil temperature or a lowering of the

lubricating oil pressure. Impending bearing failure may

be detected during periodic maintenance checks or

during engine overhauls by inspection of the bearing

shells and backs for pits, grooves, scratches, or evidence

of corrosion.

The indication of an impending failure does not

necessarily mean that the bearing has completed its

useful life. Journal bearings may perform satisfactorily

with as much as 10 percent of the load-carrying area

removed by fatigue failure. Other minor casualties may

be repaired so that a bearing will give additional hours

of satisfactory service.

Bearings should not be rejected or discarded for

minor pits or minute scratches; however, areas

indicating metallic contact between the bearing surface

and the journal do mean replacement is needed. Use a

bearing scraping tool to smooth minute pits and raised

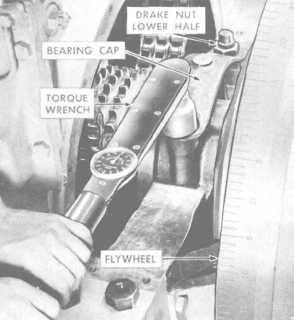

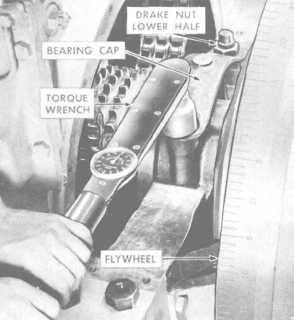

Figure 3-30.—Using a torque wrench to tighten a main bearing.

surfaces. After working on bearings, make every effort

to ensure that the bearing surfaces are clean. This also

applies to the bearing back and the connecting rod

journal Place a film of clean lubricating oil on the

journals and the bearing surfaces before you reinstall

them.

INSTALLING JOURNAL BEARINGS

Always check the markings of the lower and upper

bearing halves so you install them correctly. Many

bearings are interchangeable when new, but once they

have become worn to tit a particular journal they must

be reinstalled on that particular journal. You must mark

or stamp each bearing half with its location (cylinder

number) and the bearing position (upper or lower) to

prevent incorrect installation.

You must also pull the connecting rod bearing cap

nuts down evenly on the connecting rod bolts to prevent

possible distortion of the lower bearing cap and

consequent damage to the bearing shells, cap, and bolts.

Use a torque wrench (fig. 3-30) to measure the torque

applied to each bolt and nut assembly. Apply the same

torque to each bolt. If a manufacturer recommends the

use of a torque wrench, the specified torque will be listed

in the manufacturer’s technical manual.

Another method for pulling down the nuts evenly is

to stretch each bolt an equal amount and measure the

distance from end to end of the bolt before and after

tightening. Figure 3-31 shows the type of gauge used,

3-20