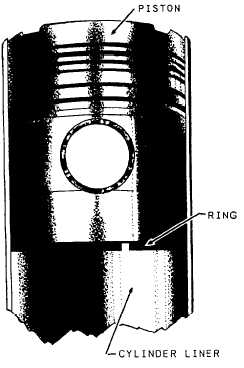

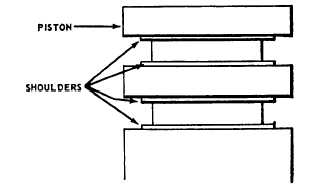

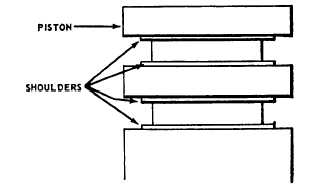

Figure 3-20.—Ring groove shoulders due to wear.

usually requires replacement of the piston since the

shoulders prevent the proper fitting of new rings.

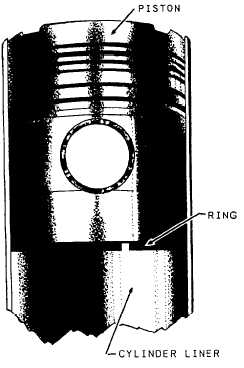

After determining that a piston is serviceable,

inspect the rings carefully todetermine whether they can

be reused. If they do not meet specifications, you must

install new rings.

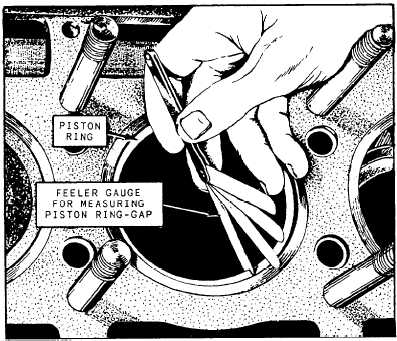

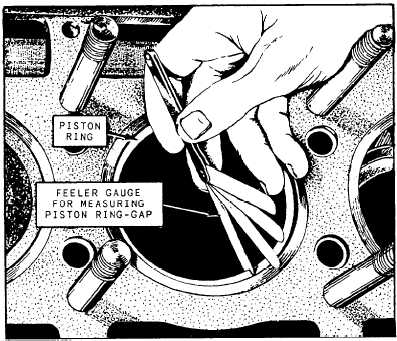

When installing rings, measure the gap with a feeler

gauge. To measure the gap, place the new rings inside

the cylinder liner (fig. 3-21, view A) or in a ring gauge.

When the gap is measured with the ring in the liner (fig.

3-21, view B), two measurements are necessary—one

just below the upper limit of ring travel, and the other

within the lower limit of travel. These measurements are

necessary because the liner may have a slight amount of

taper caused by wear. The ring gap must be within the

limits specified in the manufacturer’s technical manual.

If the gap of a new ring is less than specified, file the

ends of the ring with a straight-cut mill file to obtain the

proper gap. If the gap is more than specified, install

oversized rings.

To measure the ring gap of used rings, hold the rings

in place on the piston with a ring compressing tool (fig.

3-22). But before you measure the ring gap with the ring

on the piston, first measure the piston for wear and

out-of-roundness.

After ensuring the proper gap clearance, you can

reinstall the piston pin and connecting rod. During

reassembly and installation of a piston and connecting

rod assembly, be sure that all parts are well lubricated.

Install the rings on the piston with tools similar to those

used for ring removal. When installing piston rings,

spread them as little as possible to avoid breaking the

rings. Insert the lowest ring first. When all the rings have

Figure 3-21.–A. Leveling a piston ring. B. Measuring ring gap clearance in a cylinder bore.

3-15