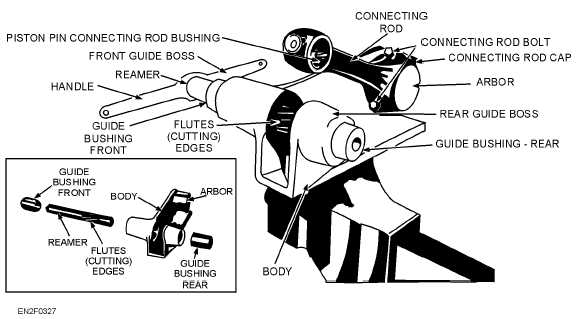

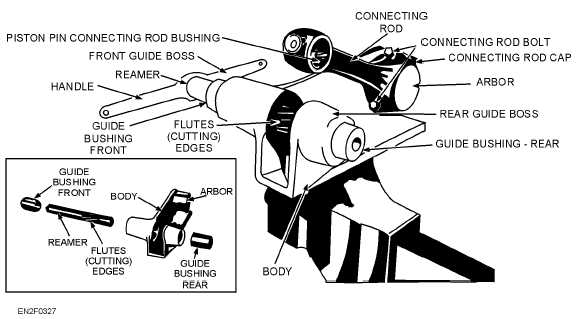

Figure 3-26.–Removing or installing a piston pin bushing.

When you insert new bushings, be sure that the bore

into which they are pressed is clean and that the oil holes

in the bushing and the oil passages in the rod are aligned.

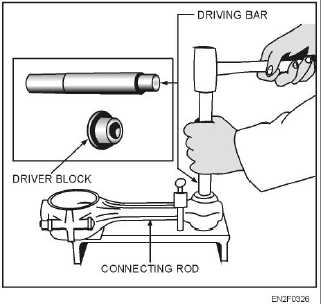

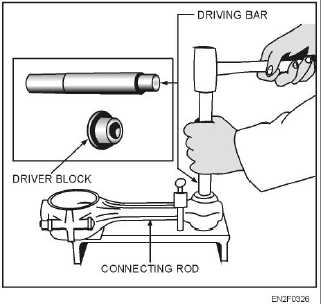

To obtain proper clearance, sometimes you will need to

ream a piston pin bushing after it has been installed.

Figure 3-27 shows equipment used to ream a bushing.

After installing a new bushing, check the alignment

of the rod with equipment such as illustrated in figure

3-28. Be sure to check the manufacturer’s technical

manual for details concerning clearances and alignment

procedures.

INSPECTING, MAINTAINING, AND

REPAIRING CONNECTING RODS

Most connecting rod troubles involve either the

connecting rod bearing or the piston pin bearing. You

can avoid these troubles by performing proper

maintenance procedures and by following instructions

in the manufacturer’s service manual. There are,

however, certain unavoidable troubles, such as cracked

connecting rods caused by defective material. Such

cracks must be discovered before they develop to a point

that the rod fails. Magniflux testing is considered the

best method for locating cracks. If you discover a crack

in a connecting rod, replace the rod; do not try to repair

it. If you have to replace a damaged rod, send it, with

other damaged parts, to a salvage center for possible

reclamation.

Do not repair defective connecting rod bolts, except

for removing small burrs by using a fine rectangular file.

If you doubt the condition of a bolt or a nut, replace it.

Check the connecting rod bore for out-of-roundness

with an inside micrometer. Make the correction and

recheck the bore. If the distortion is permanent, replace

the rod.

You can make plugged oil passages of connecting

rods serviceable by running a wire through them. In

extreme cases, you may need to drill the passages free

of foreign matter.

Figure 3-27.–Reaming equipment.

3-18