Before you reinstall a good camshaft, remove the

minor surface defects on the cams and the camshaft by

using crocus cloth or a fine stone.

INSPECTING, MAINTAINING, AND

REPLACING PISTON RINGS AND PISTONS

The following paragraphs are general procedures

for inspections, maintenance, and replacement of piston

rings and pistons. You must consult the manufacturer’s

technical manual for specific instructions.

PISTON RINGS

Over a period of time all piston rings wear. Some

stick and may even break. While you may be able to free

stuck rings and make them serviceable, you must

replace excessively worn or broken rings with new ones.

The installation of a new set of rings in an engine

requires great care. Most of the damage that is done

occurs when the rings are being placed in the grooves

of a piston or when the piston is being inserted into the

cylinder bore.

Be very careful when you remove the piston and

connecting rod from the cylinder. In most engines, you

should not remove a piston from a cylinder until you

have scraped the cylinder surface above the ring travel

area. In addition to removing all carbon, you must

remove any appreciable ridge before removing the

piston. Do not remove a ridge by grinding, as this will

allow small abrasive particles from the stone to enter the

engine. Use a metal scraper and place a cloth in the

cylinder to catch all metal cuttings. You can usually

scrape enough from the lip of a cylinder to allow the

piston assembly to slide out of the liner. After removing

the piston, you can make a more detailed inspection of

the ridge.

Finish scraping the remaining ridge, but be careful

not to go too deep. Finish the surface with a handstone.

For large ridges, you may need to remove the liner and

use a small power grinder.

With the piston and connecting rod removed, check

the condition and wear of the piston pin bushing, both

in the piston and in the connecting rod.

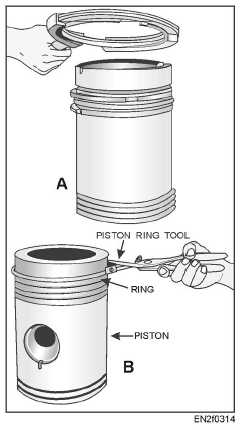

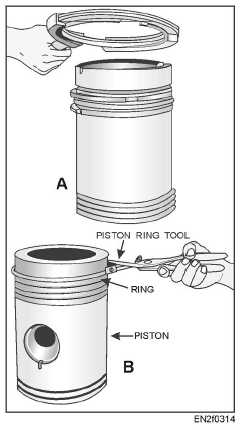

The best way to remove and install piston rings is

with a tool similar to that shown in figure 3-19. These

tools generally have a device that limits the amount the

ring can be spread and prevents the rings from being

deformed or broken.

A ring that is securely stuck in the groove will

require additional work. You may need to soak the piston

Figure 3-19.–Piston ring tools used for removal or installation.

overnight in an approved cleaning solvent or in diesel

oil. If soaking does not free the ring, you must drive it

out with a brass drift. The end of the drift should be

shaped and ground to permit its use without damage to

the lands.

After removing the rings, thoroughly clean the

piston with special attention to the ring grooves. (Diesel

oil or kerosene are satisfactory cleaning agents.) In

addition, you may need to clean excessive deposits from

the oil return holes in the bottom of the oil control ring

grooves with a twist drill of a diameter corresponding

to the original size of the holes.

Make another complete inspection after cleaning

the piston. Check all parts for any defects that could

require replacement of the piston. Give particular

attention to the ring grooves, especially if the pistons

have been in service for a long period of time. A certain

amount of enlargement of the width of the grooves is

normal, and SHOULDERING of the groove may occur.

Shouldering, as illustrated in figure 3-20, results from

the “hammering out” motion of the rings. The radial

depth of thickness of the ring is much less than the

groove depth, and while the ring wears away an amount

of metal corresponding to its own width, the metal at the

bottom of the groove remains unchanged. Shouldering

3-14