to the designated shop of the repair activity. After the

shaft has been repaired, or a new one has been made, it

is picked up and brought back to the ship by the ship’s

force. The pump is reassembled, inspected, and tested

by the ship’s force to make sure it is operating

satisfactorily.

An important thing to remember is that the repair

facility is responsible for ensuring that its personnel

repair or manufacture this this to the manufacturer’s

specifications, perform

all tests required by quality

assurance (QA), and fill out properly all the required

forms. You, however, are responsible for witnessing any

test required by QA, monitoring the status of the job at

all times, and reassembling and test operating the pump

properly. The end results will produce a reliable,

operating piece of equipment.

EQUIPMENT TESTS

As an EN2, you will assist in scheduling and

performing various tests on your equipment. The

purpose of those tests is to determine how your

equipment is performing and if there are any equipment

malfunctions. The tests are performed at various times,

such as (1) before the ship goes to the shipyard for

overhaul, (2) after post deployment, (3) during a tender

availability, or (4) as required by PMS. The tests are

performed by the ship’s force, IMA personnel, shipyard

personnel, or an inspection team (such as a Board of

Inspection and Survey [INSURV]). Detailed types of

inspections are described in COMNAVSURFLANT

Maintenance Manual, COMNAVSURFLANT INST.

9000.lC or COMNAVSURFPAC Ship and Craft

Maintenance Manual, Volumes 1 and 2, Planned

Maintenance, COMNAVSURPAC INST. 4700.lB.

Two types of inspections and tests that can be used

to “spot” impending trouble in an internal combustion

engine are called trend and spectrographic analyses. We

will now discuss and explain their importance and use

in detecting problems in internal combustion engines.

ENGINE TREND ANALYSIS

Preventive maintenance receives a great deal of

attention from everyone in the field of diesel engine

operation, since letting an engine run as long as it will

run and fixing it only after a breakdown occurs is not

only foolish, but extremely costly. On the other hand,

you would be just as foolish to constantly tear down an

engine just to inspect it. You should know that vital parts

of an engine last longer and operate better if they are not

tampered with unnecessarily. Therefore, an attempt

must be made to find a happy medium between these

two forms of maintenance.

One way to determine the condition of an engine is

by monitoring its operation. This is done by regularly

obtaining certain engine operating data and by studying,

analyzing, and comparing it with previous data. This

information is then reduced to a form that all

engineering personnel can interpret and decide whether

the engine needs to be overhauled or just temporarily

shut down for simple maintenance. For more detailed

p r o c e d u r e s , r e f e r t o N A V S E A S 9 2 3 3 - C 3 -

HBK-010/010, Diesel Engine, Over 400 BHP, Trend

Analysis Handbook

SPECTROGRAPHIC ANALYSIS

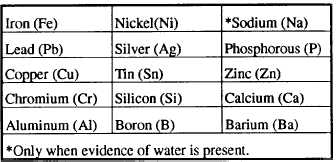

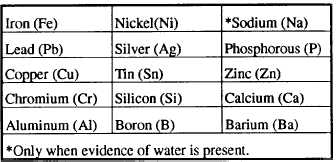

Spectrographic analysis is a method of determining

engine or equipment wear by analyzing engine oil and

hydraulic oil samples for chemicals and particles not

found in new oil or hydraulic fluid. This analysis is done

in laboratories on samples provided by ships according

to instructions given in their sampling kits.

Ships must maintain accurate records of operating

hours since major overhauls, oil changes, and samplings

to provide the testing facility with the information

requested in the sampling kit. (COMNAVSURFLANT

uses the services of the Charleston Naval Shipyard, and

COMNAVSURFPAC uses intermediate maintenance

activities (IMAs) for analyzing oil samples from

machinery employing closed lube oil/hydraulic

systems.) In addition, ships must maintain a record of

conditions found and repairs made as a result of

laboratory recommendations.

When the shipyard or IMA laboratory receives the

oil sample, a physical test and a spectrometric analysis

are performed. The physical test consists of the

following actions:

1. All samples are tested for fuel dilution, and a

report by percent volume is provided to all concerned.

1-19