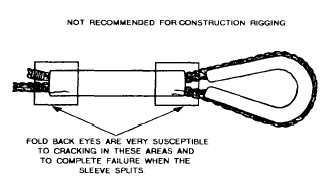

Figure 3-33.—Fold back eye and pressed metal sleeve.

The tucked eye with the pressed metal sleeve is

almost 100 percent efficient; however, the tucked eye

and serving in group 2 can develop only 70 percent of

the strength of the rope and tend to come free as the

rope unwinds. As the rope untwists, the tucks in the

eye begin to pop free.

All eye spices in group 2

should have a least five tucks, and the complete splice

should be carefully and tightly wrapped with a wire

serving to cover the whole splice.

The fold back eyes and pressed metal sleeves in

group 3 are fabricated by bending the rope to the eye

dimension required and securing the free or dead end

of the rope against the live portion of the rope by

means of a steel or aluminum sleeve set in place under

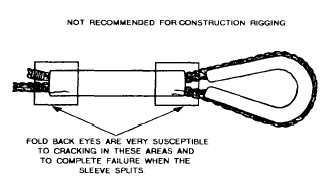

pressure. Improper swaging or split sleeves used with

fold back eye splices (fig. 3-34) can result in complete

failure without warning.

It is highly recommended

that these eye splices never be used for overhead

hoisting operations.

An alternate method of forming a soft eye in the

end of a wire rope without the use of permanent

splicing is fabricating a flemish eye splice (Molley

Hogan). The eye is simple to form, requiring a

minimum amount of tools, and does not require use of

a splicing vise. The flemish eye develops 90 percent

of the breaking strength of the wire rope.

To form a flemish eye (fig. 3-35), unlay the rope

strands 3 to 4 inches longer than twice the

circumference of the eye size desired. The wire rope

core can be cut out or laid in one section of the wire.

A simple overhand knot is made, letting the strands

lay together and adjusting the eye to the desired size.

Bend sections of the strands through the eye so that

the strands re-lay into position to form the rope.

Continue until the eye is completed. Secure the bitter

ends of the strand to the rope with lashing, seizing, or

a wire clip to prevent unlaying of the rope. Before the

sling can be put into use, it must be proof-tested and

tagged.

Proof-Testing

All field-fabricated slings terminated by

mechanical splices, sockets, and pressed and swaged

Figure 3-34.-Fold back sling failure.

3-28