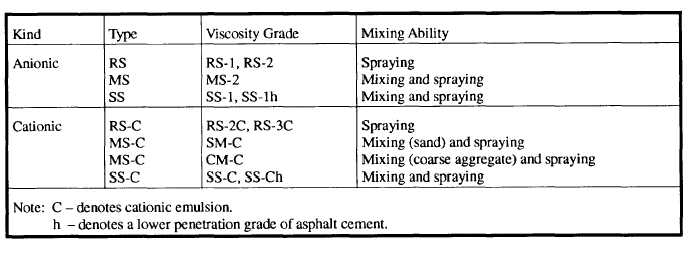

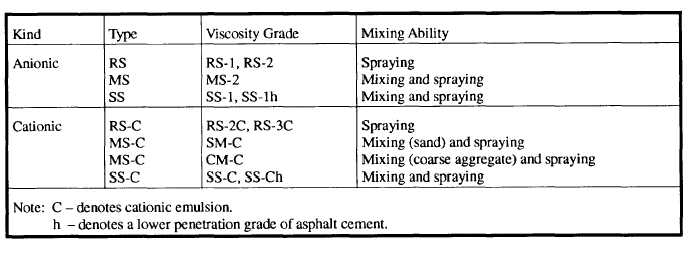

Table 8-4.-Asphalt Emulsions According to Their Electric Charge

Grades of Asphalt Cutbacks

When a great amount of cutterstock is added to a

given amount of asphalt cement, a very thin liquid

results. Viscosity grade is a measure of the relative

consistency of an asphalt bitumen after cutterstock is

added to a fixed amount of it. The grade is designated

by a number that corresponds to the lower limit of the

viscosity of asphalt cutback as determined by a standard

test. The upper limit of viscosity is defined as twice the

lower limit.

The viscosity grades of RC, MC, and SC are 70

(70-140), 250 (250-500), 800 (800-1,600), and 3,000

(3,000-6,000). The numbers in parenthesis are the lower

and upper limits of viscosity, In addition, MC has a grade

30(30-60). The grade ranges are 30 (most fluid) to 3,000

(least fluid).

Uses of Asphalt Cutbacks

Different types and grades of asphalt cutbacks are

used to meet various climate conditions for different

types of pavement. Asphalt cutbacks are usually used

for prime/tackcoats and for bituminous surface

treatments. The prevailing atmospheric temperatures

existing during construction projects are a major factor

in selecting the grade of asphalt cutback. The heavier

grades are preferred for use in warm weather; the lighter

grades in cool weather. When the preferred grade of a

given type of asphalt cutback is not available, a

comparable grade of another type may be substituted;

for example, RC-800 maybe used instead of MC-800,

or RC-70 instead of MC-70, without seriously affecting

the finished pavement.

Light grades of asphalt cutback maybe produced in

the field by adding solvents to asphalt cutback. The

composition of asphalt cutbacks, expressed in percent

of total volume, is shown in table 8-3.

Asphalt Emulsions

An asphalt emulsion is a nonflammable liquid

substance, composed of asphalt cement, water, and an

emulsifier mixed together to produce a liquid material.

Emulsions are environmentally friendly, have the same

basic uses as cutbacks and are becoming more

commonly used in the field. Asphalt and water will not

mix; therefore, a chemical agent called an “emulsifying

agent” must be added. The emulsifying agent keeps the

asphalt cement suspended in the water and controls

certain physical properties of the emulsion. Common

emulsifying agents are soaps, animal blood chemicals,

and certain specified colloidal clays in dust. When

emulsion is applied to a surface, the water and asphalt

cement break (separate), leaving a thin film of asphalt

cement.

The speed of separation, referred to as setting rate,

is the basis for designating an asphalt emulsion. The

setting rates are rapid, medium, and slow. The letter

symbols for these rates are RS, MS, and SS,

respectively.

Asphalt emulsions are classified into two types:

those that are negatively charged and those that are

positively charged (table 8-4), Emulsified asphalts may

be of either the anionic electro (negatively) charged

asphalt globules or cationic electro (positive) charged

asphalt globules. The asphalt emulsions are graded on

the basis of viscosity and grouped according to their use.

8-21