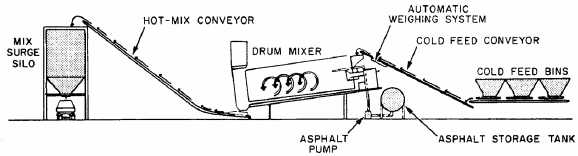

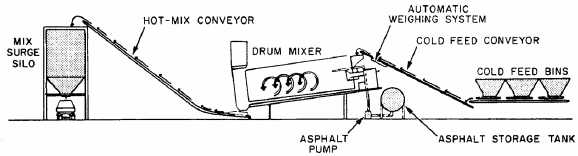

Figure 8-17.-Basic drum-mix asphalt plant

Mixing Time

Total mixing time begins when all

the combined mineral aggregates are in the

mixer and ends when the mixer discharge

gate is opened. Dry mixing time, when

specified, begins when all the combined

mineral aggregates are in the mixer and

ends with the introduction of the asphalt.

Wet mixing time begins with the start of

the asphalt application and ends with the

opening of the mixer discharge gate.

The asphalt film on aggregate is

hardened by exposure to air and heat;

therefore,

mixing

time

should

be

the

shortest time required to obtain a uniform

distribution

of

aggregate

sizes

and

a

uniform

coating

of

asphalt

on

all

aggregate

particles.

The

speed

of

the

mixer shafts and the arrangement and pitch

of the paddles are factors governing the

efficiency of the mixing.

To aid further the operation of a

continuous mix plant, you can add or

extend several automatic controls.

These include the following:

1. Automatic burner controls

2. Automatic mix discharge

3. Automatic mixer and gradation

cutoffs

in

case

of

hot-bin

shortage

or

improper feed

4.

Electric

interlocks

that

shut

down the complete plant in case of a

failure anywhere in the electric system

The

operator’s

manual

for

the

particular plant being used gives details

on

the

setup

and

adjustments

of

the

automatic

equipment

included

with

the

plant.

NOTE:

Normally

all

automatic

systems have manual override. You should

know where it is located and how to use

it.

See

the

manufacturer’s

manual

for

specific

details.

DRUM-MIX ASPHALT PLANT

The drum-mix plant is shown in

figure 8-3. The mixing drum for which the

plant

is

named

is

very

similar

in

appearance to the batch plant dryer drum.

The difference between the two is that in

a drum-mix plant the aggregate is not only

dried and heated within the drum, but it

is also mixed with the asphalt cement. In

a drum-mix plant, there are no gradation

screens,

hot

bins,

weigh-hoppers

or

pugmills.

Aggregate

gradation

is

controlled at the cold feed.

The basic plant consists of a cold-

feed system, a rotating drum dryer, an

asphalt

proportioning

and

dispensing

system, and a surge silo (fig. 8- 17). The

ease of setup and operation of the drum-

mix plant makes it the ideal machine for

operations.

Aggregate Storage and Feed

Aggregate

gradation

and

uniformity

are

entirely

dependent

on

the

cold-feed

system. Proper care must be exercised not

only in producing the aggregate but also

in storage. Aggregates used for drum-mix

plants

must

be

received,

handled,

and

stored to ensure there is no danger of

contamination

or

intermingling.

Stockpiles must be properly graded

and

split

into

different

sized

fractions

to

control

the

gradation

of

the

mix

properly.

Uncorrected

segregated

stockpiles

will

result

in

mix

gradation

difficulties.

The

plant

supervisor

should

establish and maintain stockpiles in the

most economical manner and correct any

deficiencies

in

uniformity

before

the

aggregate is fed into the mixing plant.

Since

the

typical

drum-mix

plant

does

not

have

a

gradation

unit,

the

aggregate

must

be

proportioned

before

entering

the

mixing

drum.

This

is

accomplished with a multiple-bin cold-feed

system

equipped

with

precision

belt

feeders

for

control

of

each

aggregate.

8-16