2. Install the wedge socket carefully to ensure

the wire rope carrying the load is in direct alignment

with the eye of the socket clevis pin so the load pull is

direct.

3. Place the socket upright and bring the rope

around in a large, easy-to-handle hoop. Extend the

dead end of the wire rope from the socket for a

distance of a least one rope lay length. Insert the

wedge in the socket, permitting the rope to adjust

around the wedge.

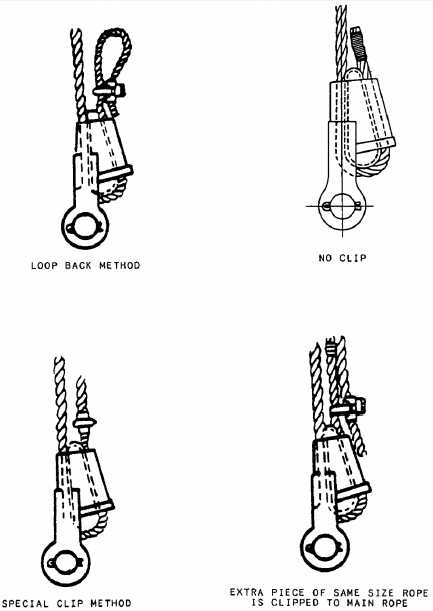

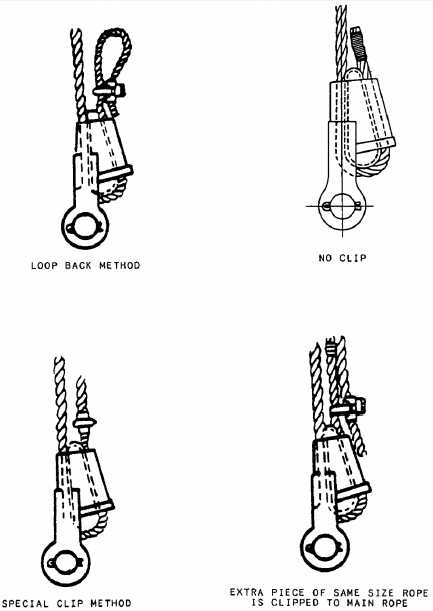

4. As a safety precaution, install a wire rope

clamp on the dead end of the wire rope that comes

out of the wedge socket (fig. 3-7). Measure the

distance from the base of the wedge socket to the

clamp. This measurement is used as a guide to check

if the wire rope is slipping in the wedge socket

5. Secure the socket to a support and carefully

take a strain on the live side of the rope to ensure the

proper initial seating of the wedge. Increase the load

gradually until the wedge is fully seated. Avoid

applying sudden shock loads.

Hook Block Inspection

The hook block and the hook is part of the

ODCL inspection. The operator must inspect the hook

block for cleanliness, binding sheaves, damaged or worn

Figure 3-7.—Wedge socket clip method.

3-9