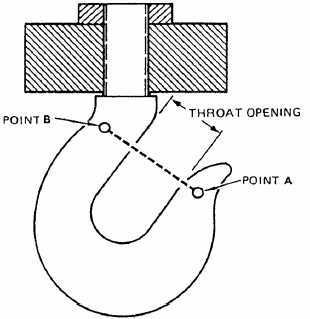

sheaves, worn or distorted sheave pins, broken bolts,

and worn check weights (fig. 3-8).

The hook is inspected for damage, excessive

wear to the hook safety latch, hook swivel trunnions,

thrust collar, and securing nut. Also, the hook is

inspected for damage or missing lubrication fittings,

proper lubrication, cracks and gouges, and if visibly

bent or twisted.

Before weight testing the crane, check the

hook block certification. Every fifth certification, the

hook block should be magna-fluxed and noted on the

certification document. The magna-fluxed procedure

is normally performed by the Public Works Center.

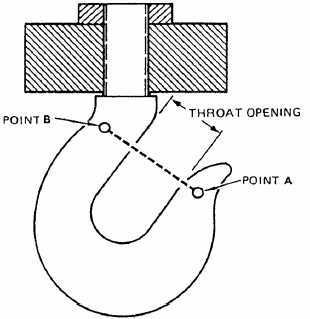

Part of the weight-testing procedure is to

document the before and after hook throat opening

tram point measurement (fig. 3-9). The before

measurement is performed before the weight test of

the crane.

Sheave Inspection

Sheaves are located in the hook block, boom

point, boom bridle, gantry, and boom mast. Sheaves

are installed basically anywhere wire rope must turn

or bend. Sheaves rotate on either bearings or

bushings that are inspected for discoloration (due to

excessive heat), metallic particles, chips or displaced

Figure 3-9.-Hook throat measurement.

metal, broken or distorted bearing retainer or seals,

adequate lubrication, and tight bearing caps.

The sheave inspection (fig. 3-10) is the

inspection for wear and damage, wear in the wire

rope sheave groove, loose or damaged sheave guards,

and worn bearings and pins.

Figure 3-8.—Hook and block inspection points.

3-10