power unit, and the relief valves are located at the inside

of the left door. The return and suction filters are located

at the top of the hydraulic tank.

A pressure-compensated valve to change rod rpm

according to drilling conditions is located at the inside

of the left door.

The four pumps provide oil as follows:

l Pump one provides oil for right side tramming

and slow and fast feed drilling.

. Pump two provides oil for left side tramming,

drill, and fast feed.

. Pump three provides oil for high-speed

tramming, rotation, and cooler.

. Pump four provides oil for high-speed tramming,

dust collector, centralizer, cylinders, and auto rod

changer (if so equipped).

Oil Cooler

The oil cooler maintains safe temperatures for

hydraulic oil and compressor oil in all climates and is

located at the top of the power unit. At low

temperatures, the oil bypasses the coder through the

cold bypass valve.

Air System

The air system consists of a compressor air end,

receiver tank, blow air circuit, dust collector (if so

equipped), and air lube system.

The air end is connected to the engine with a flexible

coupling. The compressed air is delivered to the

receiver tank, located at the backside of the power unit.

The compressed air, mixed with compressor oil, is

separated from the oil in the receiver tank and is

distributed to each system. The separated compressor

oil is sent to the oil cooler from the receiver tank under

pressure. The compressor discharge air volume is 230

cfm, and the discharge air pressure is 100 psi.

NOTE: A common cause of low discharge air

pressure is a clogged orifice muffler, located on the

upper rear left comer of the rock drill.

The dust collector is equipped with a stepping pulser

that sends discharged air every 20 seconds to knock off

the cuttings on the filter into the dropout chute, located

at the bottom of the collector.

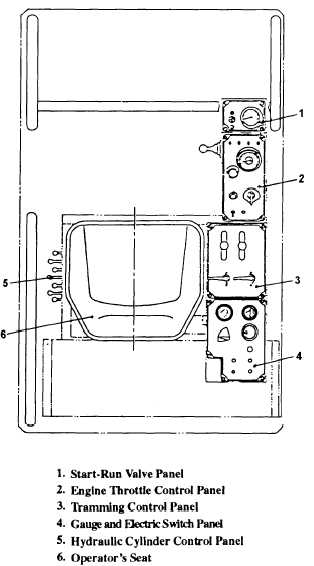

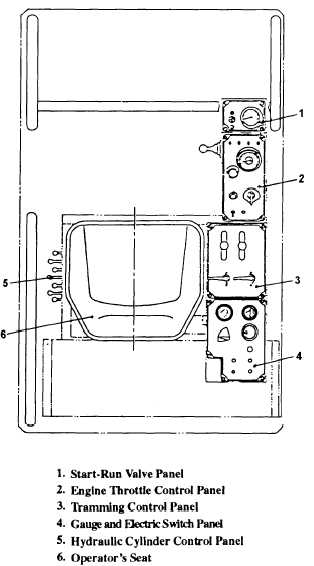

CONTROL CONSOLE

Controls on the drill guide are only for drilling and

cylinder movement.

All other engine controls,

tramming valve, and cylinder valve are located around

the operator’s seat, as shown in figure 14-22.

BOOM

The rock drill is equipped with an expendable boom,

commonly called a mast. The boom can vary 5 feet in

length from the fully retracted to the fully extended

position. The extendable booms are constructed of

square steel tubing with a dump base holder at the front

end and a clevis at the rear end. The clevis is hinged to

a pedestal that is held in the boom base clevis by a

kingpin.

Figure 14-22.—Operator's control console.

14-17