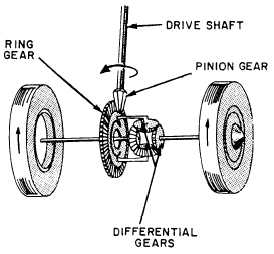

Figure 2-15.-Gears used in final drives.

cars, this reduction varies between 3 to 1 and 5 to 1. In

trucks, it can vary from 5 to 1 to as much as 11 to 1.

The gear ratio of a final drive with bevel gears is

frond by dividing the number of teeth on the driven or

ring gear by the number of teeth on the pinion. In a

worm gear final drive, the gear ratio is found by counting

the number of revolutions of the worm gear for one

revolution of the driven gear.

Most final drives are gear type. Hypoid differential

gears permit a lower body design. They permit the

bevel-driven pinion to be placed below the center of the

ring gear, thereby lowering the propeller shaft, as shown

in figure 2-15.

Worm gears allow a larger speed

reduction and are sometimes used on large trucks.

Spiral bevel gears are similar to hypoid gears and are

used in both passenger cars and trucks to replace spur

gears that are too noisy.

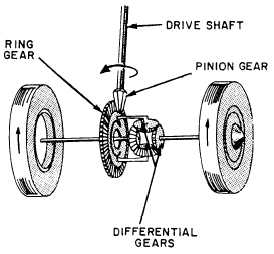

DIFFERENTIALS

Another important unit in the power train is the

differential, which is a type of final drive. As shown in

figure 2-16, the differential is located between the axles

and permits one axle shaft to turn at a different speed

from that of the other. At the same time, the differential

transmits power from the transmission/transfer case to

both axle shafts. The variation in axle shaft speed is

Figure 2-16.—Differential operation.

necessary when the vehicle turns a corner or travels over

uneven ground. As a vehicle travels around a curve, the

outer wheel must travel faster and further than the inner

wheel. Without the differential, one rear wheel would

be forced to skid when turns are made, resulting in

excessive tire wear as well as making the vehicle more

difficult to control.

Some trucks have a differential lock to keep one

wheel from spinning. This is a simple dog clutch,

2-11