DIESEL ENGINE COMPRESSION STROKE.—

The piston is at bottom dead center at the beginning of

the compression stroke, and, as the piston moves

upward, the air compresses. As the piston reaches top

dead center, the compression stroke ends (fig. 1-10,

view B).

DIESEL ENGINE POWER STROKE.— The

piston begins the power stroke at top dead center. The

air is compressed to as much as 500 psi and at a

compressed temperature of approximately 1000°F. At

this point, fuel is injected into the combustion chamber

and is ignited by the heat of the compression. This

begins the power stroke. The expanding force of the

burning gases pushes the piston downward, providing

power to the crankshaft. The diesel fuel will continue to

bum through the entire power stroke (a more complete

burning of the fuel) (fig. 1-10, view C). The gasoline

engine has a power stroke with rapid combustion in the

beginning, but little to no combustion at the end.

DIESEL ENGINE EXHAUST STROKE.— As

the piston reaches bottom dead center on the power

stroke, the power stroke ends and the exhaust stroke

begins (fig. 1-10, view D). The exhaust valve opens,

and, as the piston rises towards top dead center, the burnt

gases are pushed out through the exhaust port. As the

piston reaches top dead center, the exhaust valve closes

and the intake valve opens. The engine is now ready to

begin another operating cycle.

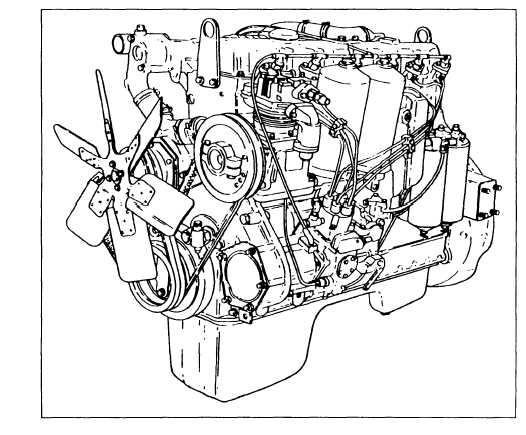

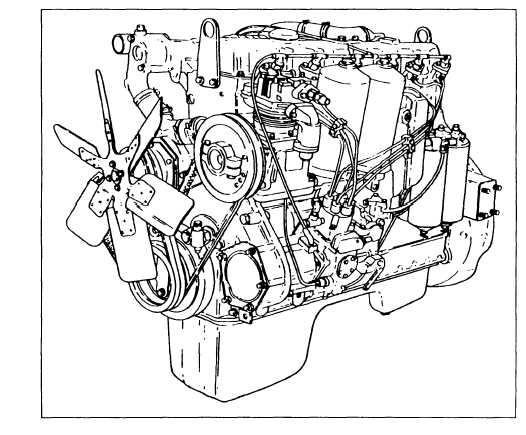

Multifuel Engine

The multifuel engine (fig. 1-11) is basically a

four-stroke cycle diesel engine with the capability of

operating on a wide variety of fuel oils without

adjustment or modification. The fuel injection system is

equipped with a device called a fuel density

compensator that varies the amount of fuel to keep the

power output constant regardless of the type fuel being

used. The multifuel engine uses a spherical combustion

chamber (fig. 1-12) that aids in thorough fuel and air

mixing, complete combustion, and minimizes knocks.

NOTE: Because of environmental pollution

controls and the development of more efficient diesel

engines, the multifuel engine is being phased out.

Figure 1-11.—Multifuel engine.

1-8