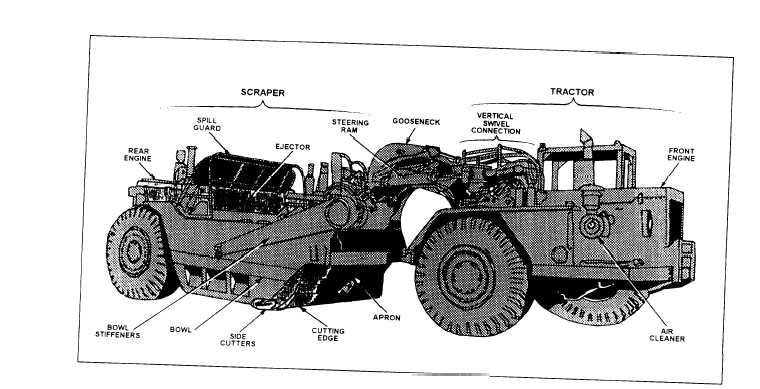

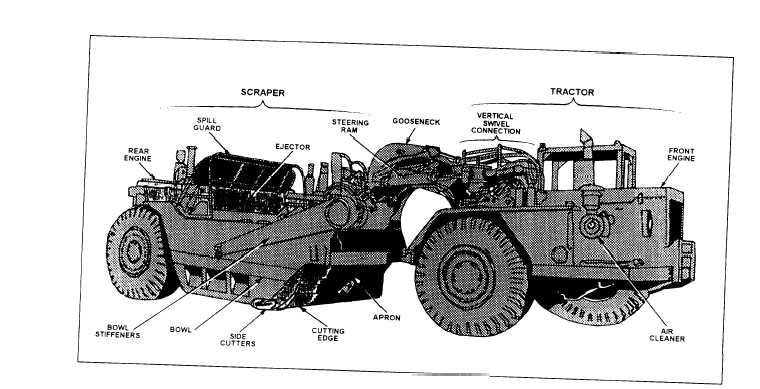

Figure 10-35.—Scraper nomenclature.

elevating scraper or self- loading scraper. This scraper,

on most projects, requires no push cat for loading and is

ideal for small- to medium-size earthmoving jobs. The

scraper loads its pan from the top by means of a paddle

wheel elevator after the material has been cut by the

cutting edge. Material is not forced to the top as on other

scrapers. The loaded material can also be unloaded by

the paddle wheels, giving the operator more control of

the desired depth of fill.

A variety of scrapers are used in the NCF. Each

operator is responsible for reading the operator’s

manual to obtain detailed information about each make

and model.

SCRAPER COMPONENTS

The scraper is made in two sections: the tractor and

the scraper. The tractor contains the engine, the drive

train and wheels, the hydraulic pumps, and the

operator’s cab. The tractor is connected to the scraper

by a vertical kingpin swivel connection usually in two

parts with upper and lower pins. When you are steering,

this connection permits turns of 85 to 90 degrees to each

side of the center line of the scraper. There is also a

longitudinal horizontal hinge that permits the two

sections to tip independently from side to side.

The gooseneck of the scraper arches up to allow

space for the tractor wheels to roll under it on turns. The

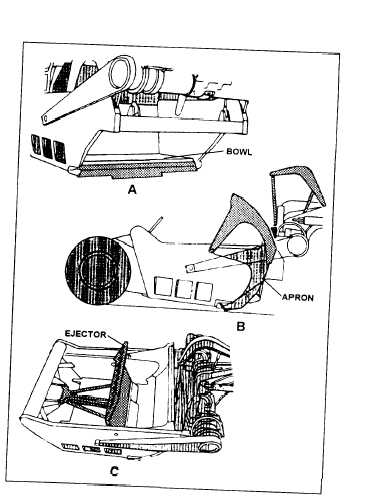

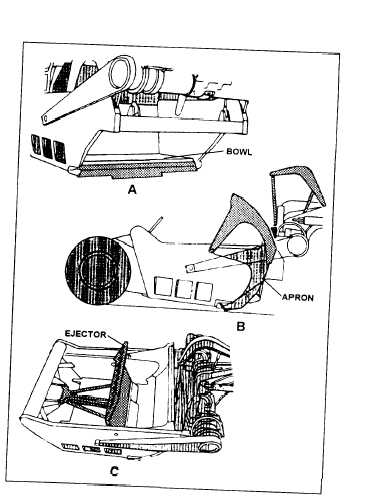

Figure 10-36.—Scraper bowl, apron, and ejector.

10-18