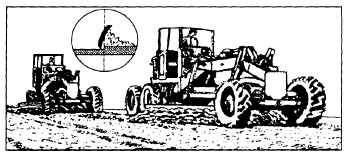

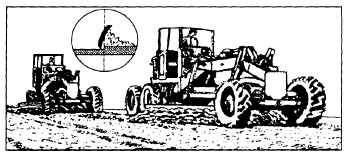

the blade should be extended well to the side and angled

to side cast the windrow to the inside of the rear tires.

The pile is reduced by using a series of side cuts, as

shown in figure 10-31. Piles to be spread by a grader

should be spread dumped as much as possible. The load

to be spread is limited by the power and traction of the

grader.

When there is not enough room to use the wide side

reach and the piles of material are not too high, the front

wheels may be driven over the piles. The front axles

push the top off the pile, and the blade cuts as much as

power permits. The blade should be positioned well

below its highest point, so when the grader gets hung up

on the piles and loses traction, the blade can be raised to

restore the weight to the rear wheels. When traction is

lost and the tires spin, unnecessary tire wear increases.

Road Maintenance

The ability of the grader to blade mix materials used

as road surfaces is an important function in road

maintenance.

When blade mixing, pitch the blade

slightly forward and angled at about 30 degrees. This

position gives the widest possible spread with maximum

mixing action. In mixing, move the windrow from side

to side by successive cuts with the blade.

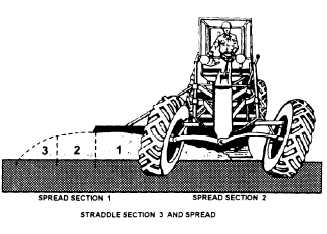

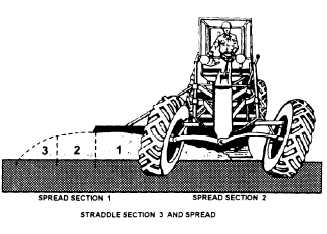

To increase production, use several graders to

operate, one behind another, on the same windrow (fig.

10-32). When the mixture is wet, mixing should

continue until the mixture is dry. After mixing, the

material is again side tasted into a windrow before

spreading. During mixing, more bitumen or cement can

be applied to any lean sections. All particles of the

completed mix should be coated and uniform in color.

Figure 10-31.—Wide side reach.

Figure 10-32.—Blade-mixing operation.

Blade-mixing operations are performed as rapidly

as possible, consistent with the skill of the operator and

the condition of the surface being maintained.

However, when the grader is operated too fast, it will

tend to bounce and give the surface a washboard

appearance that will take additional time and passes to

connect. When washboarding is not corrected, it will

create unnecessary wear and tear on traffic using the

road or work area.

Snow Removal

Graders can be used for snow removal in the same

way as a snowplow. The blade and circle are adjusted

to side cast snow and slush the same as if side casting

road materials. When the cutting edges are not removed

and replaced with a strip of hard rubber bolted to the

moldboard, raise the blade at least 1/2 to 1 inch when

removing snow from uneven pavement or a runway

surface.

NOTE: Failure to make proper blade adjustments

can result in not only damaging the cutting edges,

moldboard, or grader, but also in gouging and tearing up

the road or runway surface.

Finish Grading

Finish grading is a fine cut or fill of a surface to get

the final desired elevation. This phase of a grading

operation is called blue topping. Blue topping takes

time and patience even for experienced operators.

When performing blue topping operations, make

sure the grader cutting edges are not worn, the tires are

the same size with the correct air pressure, and the tires

are pointed in the right direction. Front tire treads

should be pointed toward the rear, and rear tire treads

should be pointed toward the front. Adjust the blade

pitch all the way forward to scrape instead of cut.

10-14