spiral. Figure 7-15, view A, shows how to change

the direction of the spiral. The ring is then

stretched slightly, as shown in view B prior to

installation into the groove. While the TFE ring

is being inserted into the groove, rotate the

component in a clockwise direction. This will tend

to expand the ring diameter and reduce the

possibility of damaging the ring.

When TFE spiral rings are being installed in

external grooves, the ring should have a left-hand

spiral. As the ring is being inserted into the

groove, rotate the component in a clockwise

direction. This action will tend to contract the ring

diameter and reduce the possibility of damaging

the ring.

In applications where a leather backup ring

is called for, place the smooth-grained side of the

leather next to the ring. Do not cut leather backup

rings. Use a leather backup ring as one continuous

ring and lubricate the ring prior to installing it,

particularly the smaller sizes. If stretching is

necessary for proper installation, soak the backup

ring in the system fluid or in an acceptable

lubricant at room temperature for at least 30

minutes.

or two backup rings, depending upon the specific

seal groove application and width. The Quad-

Ring® seal works well in, both hydraulic and

pneumatic systems.

Many Quad-Ring® seal sizes have been

assigned NSNs and are stocked in the Federal

Supply System. Quad-Ring® seals in manu-

facturer’s sizes designated as Q1 through Q88 are

interchangeable with O-rings conforming to

AN6227. Likewise, Quad-Ring® seals in com-

mercial sizes Q101 through Q152 are inter-

changeable with O-rings conforming to AN6230

in the respective dash sizes from –1 through–52.

Therefore, the Quad-Ring® seal stock part

number uses the AN standard O-ring designations

AN6227 and AN6230 and the commercial Q dash

number designation. For example, NSNs are

found under such reference part numbers as

AN6227Q10 and AN6230Q103. If the letter Q

does not follow AN6227 or AN6230, the part

number is an O-ring not a Quad-Ring® seal.

If Quad-Ring® seals are not available for

maintenance actions, appropriate sized O-rings

can be installed and they work satisfactorily.

QUAD-O-DYN® SEALS

QUAD-RINGS

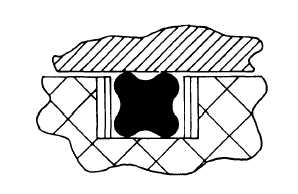

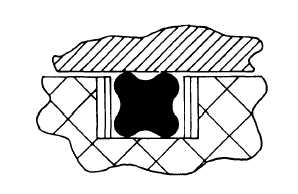

The Quad-Ring® seal is a special configura-

tion ring packing, manufactured by the Minnesota

Rubber. As opposed to an O-ring, a Quad-

Ring® seal has a more square cross-sectional

shape with rounded corners (fig. 7-16). The Quad-

Ring® seal design offers more stability than the

O-ring design and practically eliminates the

spiraling or twisting that is sometimes encountered

with the O-ring.

Quad-Rings® seals are completely inter-

changeable with O-rings in the sizes offered by

the manufacturer. They may be installed with one

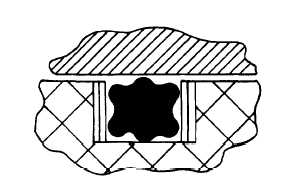

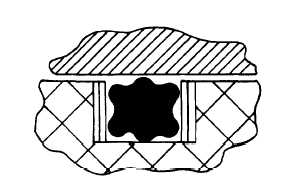

The Quad-O-Dyn®, also manufactured by

Minnesota Rubber, is a special form of the

Quad-Ring. The Quad-O-Dyn differs from the

Quad-Ring in configuration (fig. 7-17), is harder,

is subject to greater squeeze, and is made of a

different material. The Quad-O-Dyn® seal also

works well in O-rings glands.

The Quad-O-Dyn® is used in relatively few

applications. However, for difficult dynamic

sealing applications, the Quad-O-Dyn® can

perform better than the Quad-Ring. Quad-O-

Dyn® rings are installed in submarine hydraulic

systems plant accumulators.

Figure 7-16.—Quad-Ring.

7-15

Figure 7-17.—Quad-O-Dyn® seal.