CHAPTER 8

MEASUREMENT AND PRESSURE

CONTROL DEVICES

For safe and efficient operation, fluid power

systems are designed to operate at a specific

pressure and/or temperature, or within a pressure

and/or temperature range.

You have learned that the lubricating power

of hydraulic fluids varies with temperature and

that excessively high temperatures reduce the life

of hydraulic fluids. Additionally, you have

learned that the materials, dimensions, and

method of fabrication of fluid power components

limit the pressure and temperature at which a

system operates. You have also learned of means

of automatically controlling pressure in both

hydraulic and pneumatic systems.

Most fluid power systems are provided with

pressure gauges and thermometers for measuring

and indicating the pressure and/or the tempera-

ture in the system. Additionally, various tempera-

ture and pressure switches are used to warn of an

adverse pressure or temperature condition. Some

switches will even shut the system off when an

adverse condition occurs. These devices will be

discussed in this chapter.

PRESSURE GAUGES

Many pressure-measuring instruments are

called gauges. However, this section will be

restricted to two mechanical instruments that

contain elastic elements that respond to pressures

found in fluid power systems—the Bourdon-tube

and bellows gauges.

BOURDON TUBE GAUGES

The majority of pressure gauges in use have

a Bourdon-tube as a measuring element. (The

gauge is named for its inventor, Eugene Bourdon,

a French engineer.) The Bourdon tube is a device

that senses pressure and converts the pressure to

displacement. Since the Bourdon-tube displace-

ment is a function of the pressure applied, it may

be mechanically amplified and indicated by a

pointer. Thus, the pointer position indirectly

indicates pressure.

The Bourdon-tube gauge is available in

various tube shapes: curved or C-shaped, helical,

and spiral. The size, shape, and material of the

tube depend on the pressure range and the type

of gauge desired. Low-pressure Bourdon tubes

(pressures up to 2000 psi) are often made of

phosphor bronze. High-pressure Bourdon tubes

(pressures above 2000 psi) are made of stainless

steel or other high-strength materials. High-

pressure Bourdon tubes tend to have more circular

cross sections than their lower-range counterparts,

which tend to have oval cross sections. The

Bourdon tube most commonly used is the

C-shaped metal tube that is sealed at one end and

open at the other (fig. 8-1).

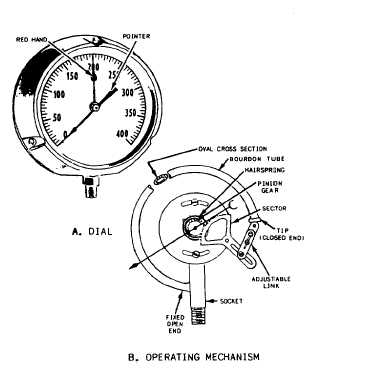

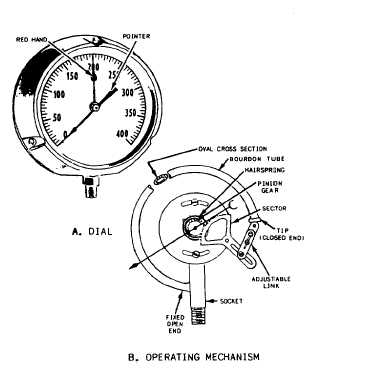

Figure 8-1.—Simplex Bourdon-tube pressure gauge.

8-1