U-CUPS AND U-PACKINGS

The distinction between U-cups and

U-packings results from the difference in materials

used in their fabrication. The U-cup is usually

made of homogeneous synthetic rubber;

U-packings are usually made of leather or fabric-

reinforced rubber. Special aspects of each type will

be discussed separately. However, all U-cups and

U-packings have cross sections resembling the

letter U. Both types are balanced packings, both

seal on the ID and the OD, and both are applied

individually, not in stacks like V-rings. Size

differences between U-cups and U-packings are

usually substantial enough to prevent inter-

changeability. There are a few sizes with smaller

diameters and cross sections that may appear

to be dimensionally equivalent but are not.

Therefore, U-packings should not be substituted

for U-cups (or vice versa) in any installation.

U-CUPS

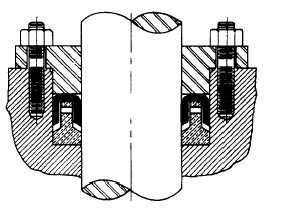

The U-cup (fig. 7-18) has been a popular

packing in the past because of installation ease

and low friction. U-cups are used primarily for

pressures below 1500 psi, but higher pressures are

possible with the use of antiextrusion rings. For

double-acting pistons, two U-cups are installed

in separate grooves, back-to-back or heel-to-heel.

Two U-cups are never used in the same groove.

This heel-to-heel type of installation is common

for single-acting (monodirectional) seals, such as

U-cups and V-rings, and is necessary to prevent

a pressure trap (hydraulic lock) between two

packings. Installation of two U-cups with sealing

lips facing each other can result in hydraulic lock

and must be avoided.

Leather U-Packings

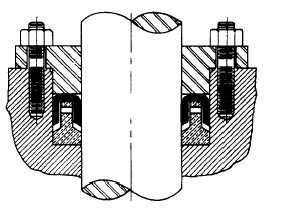

As a rule, leather U-packings are made with

straight side walls (no flared sealing lips). See

figure 7-19. The leather may be chemically treated

or otherwise impregnated to improve its per-

formance. Leather U-packings are available in

standard sizes conforming to industrial specifica-

tions. For support, the cavity of the U-packing

should contain a metal pedestal ring or should be

filled with a suitable material. Leather U-packings

with an integral pedestal support have been

installed in some submarine steering and diving

ram piston seals.

CUP PACKINGS

Cup packings resemble a cup or deep dish with

a hole in the center for mounting (fig. 7-20). Cup

seals are used exclusively to seal pistons in both

low- and high-pressure hydraulic and pneu-

matic service. They are produced in leather,

homogeneous synthetic rubber, and fabric-

reinforced synthetic rubber. Although the cup

packing lip flares outward, the rubbing contact

is made at the lip only when the fluid pressure is

low. As the fluid pressure increases, the cup heel

expands outward until it contacts the cylinder

wall, at which point high-pressure sealing is in

effect. As the pressure loading shifts the sealing

line to the cup heel, the lip is actually pulled into

the cup and away from the cylinder wall. On the

return stroke when the pressure is relaxed, the heel

will shrink slightly, leaving only the lip in contact

with the wall, avoiding unnecessary wear at the

heel.

For reciprocating pistons, two cups installed

back-to-back in separate glands are required.

FLANGE PACKINGS

Flange packings are used exclusively in low-

pressure, outside-packed installations, such as rod

Figure 7-18.—Typical U-cup seal.

Figure 7-19.—U-packing.

7-16