the base metal. A thin, irregular bead will result if

Inadequate shielding gas flow resulting from

you move forward too rapidly. Undercutting may

a low cylinder pressure, from restrictions in

result if you move the gun forward too slowly. A

the gas passages of the equipment, or from

good bead is uniform in width and height. The

improper adjustment of the flowmeter

ripple is uniform, and there is no overlap or

undercut at the edges.

Excessive weaving or whipping of the

welding gun

Some of you may want to move the gun along

the line of weld with a steady forward motion.

Poor fit-up of parts

Others prefer to run a bead with a reciprocating

technique like that shown in figure 10-53. When

Improperly cleaned base metal, or dirty

you use this technique, strike the arc and then

welding wire

slowly move the gun forward along the line of weld

about one-half inch and then back about one-fourth

Nonuniform wire-feed speed

inch. Continue this one-half inch forward and

one-fourth inch backward motion along the line of

Welder fatigue is often the cause of poor weld

weld. If you want a wide bead, use a side weave.

quality and low output. You will learn that the

Here, the gun is moved uniformly back and forth

quality and quantity of your work improves as you

across the line of weld while steadily moving along

learn to weld comfortably. Out-of-position welding

the line of weld. The width of the bead determines

is usually more awkward than flat position;

the amount of sidewise movement.

therefore, arrange the work for flat position welding

whenever possible for economy and quality.

Although GMA welding does not require the

use of a flux, it does require that the base metal be

Satisfactory weld results also depend on good

clean. Aluminum and aluminum alloys should be

maintenance of the GMA equipment. Maintenance

cleaned with an approved compound, or with a

procedures are outlined in the manufacturer's

stainless-steel wire brush. Any grease should be

technical manual furnished with the equipment.

removed with a solvent before cleaning with a

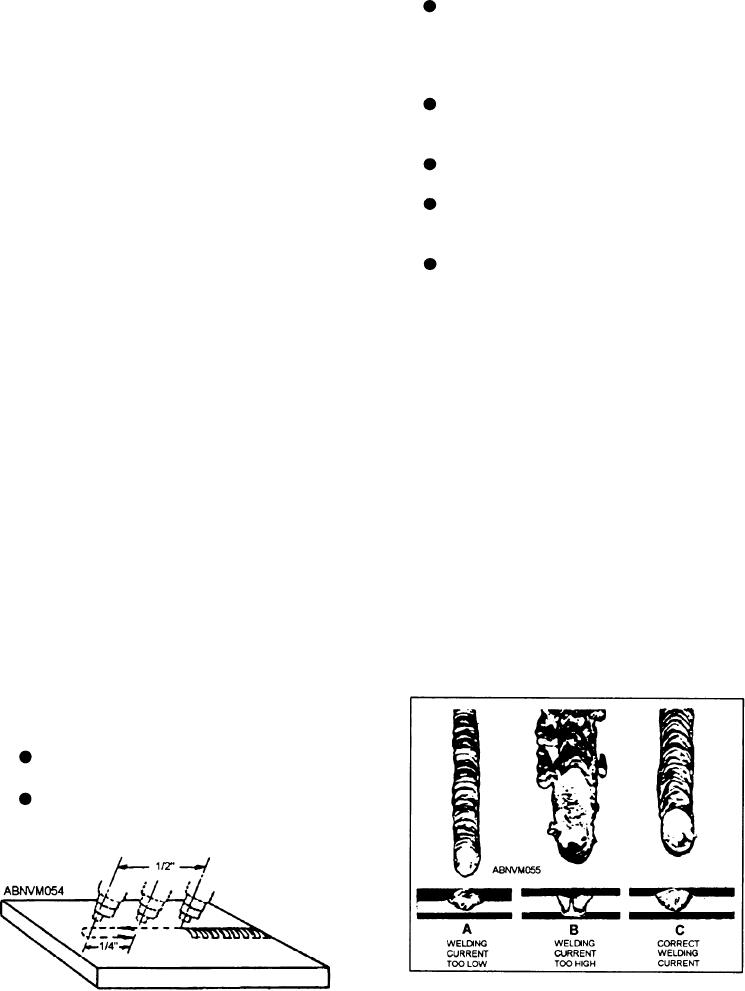

Weld beads made with too low, too high, and the

compound. Stainless-steel wire brushes that have

correct current are shown in figure 10-54.

picked up grease should be cleaned with a solvent

before they are used to clean aluminum for welding.

Notice the lack of penetration and "ropy"

appearance of the weld bead made with insufficient

Once you get the feel of welding with GMA

welding current. Also, note the deep penetration

equipment, you will probably find that the

techniques are less difficult to master than many of

the other welding procedures. However, there are

some pitfalls. Porous welds may result from the

following causes:

Low arc voltage (less than 26 volts)

Low welding current

Figure 10-54.--Weld bead characteristics determined by

Figure 10-53.--Reciprocating technique for GMA welding.

welding current.

10-43