for GMA welding is designed to initiate gas

coverage and automatically feed the aluminum

electrode into the weld area when the arc is struck.

A welding pool is formed immediately when the arc

is established. Welding progresses by moving the

welding gun along the line of the joint at a rate to

build up a bead of the desired dimensions. The

electrode and weld pool are protected from

oxidation by the shield of gas during welding. No

flux is required.

GMA Welding Equipment

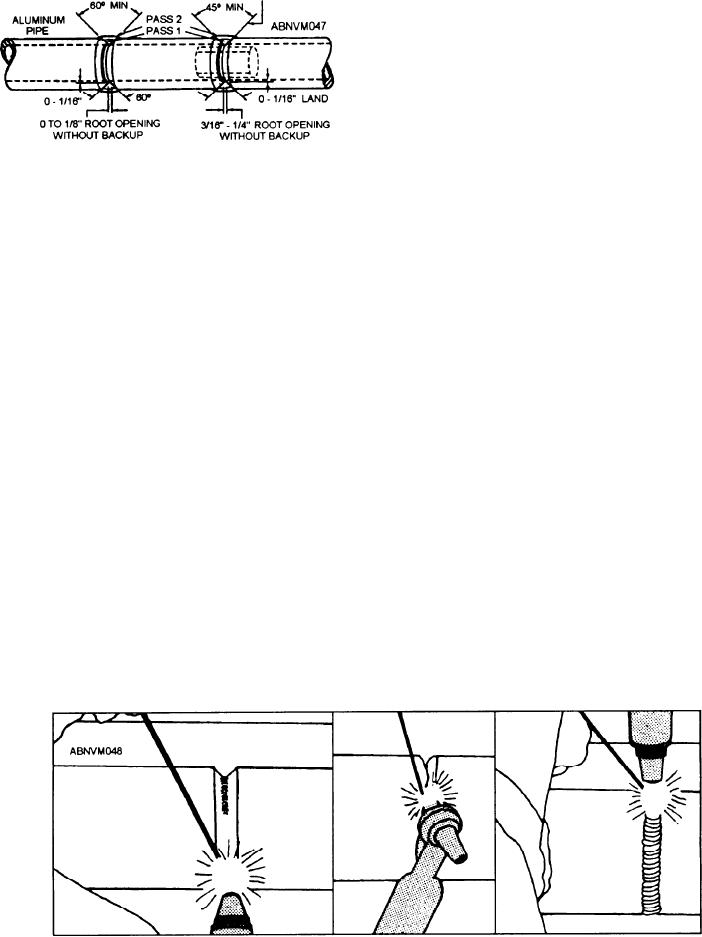

Figure 10-46.--Joint design and weld pass sequence

horizontal fixed-position multipass (GTA) welding.

Numerous types and models of GMA welding

equipment are used in the Navy. They all have the

Most welders prefer to use a backup ring for

same basic requirements. Each must have a source

pipe welding when possible because it makes the

of DCRP welding current, a wire feed unit for

operation easier. With backup, the joint fit and

feeding the wire filler metal, a control unit that

penetration control are not so critical. You should,

controls the automatic feed of the wire filler metal

however, learn to make the weld without a backup

and shielding gas, and a welding gun for directing

ring.

the wire filler metal and shielding gas to the weld

area. Figure 10-49 shows one type of GMA welding

Horizontal fixed-position pipe welding is often

equipment that is used quite often for short run

considered a test to qualify for welding in any

welds and welds in hard-to-get-to places that are

position. It includes welding in the flat, vertical, and

inaccessible to larger welding guns.

overhead positions. Figure 10-47 shows the

technique of torch and filler rod handling.

The 200 dc amp rectifier welder shown in figure

10-49 was designed specifically for the GMA

GAS METAL-ARC (GMA)

welding process and is a constant potential power

WELDING PROCESS

source. The constant potential power source

compensates for changes in arc length, thus

The GMA welding process is also known as gas

providing more uniform welding.

consumable electrode welding (fig. 10-48). It uses

a dc (reverse polarity) and a shield of argon or

The welding gun shown in figure 10-49 contains

helium or a mixture of both. A small diameter

the wire drive motor and drive roll assembly, the

aluminum wire serves both as electrode and filler

control switch for control of the wire feed and gas

metal and is fed automatically from the welding gun

flow, and a replaceable l-pound spool of wire filler

at high speed. Commercially available equipment

Figure 10-47.--Techniques of torch and filler rod handling for tubular sections.

10-38