A and B. The correct positioning of the torch and

addition of the filler metal at the weld pool edge to

prevent undercutting when making a horizontal

position fillet weld is shown in figure 10-41.

Vertical-Position Multipass Fillet

and Butt Welds

This exercise will brief you on the technique of

vertical position welding. You will need 1/2" by 6"

by 12" EC aluminum plate and 3/16-inch diameter

1100 alloy filler rod or any other recommended

parent plate-filler rod combination. You will also

need a backing strap, if one is used.

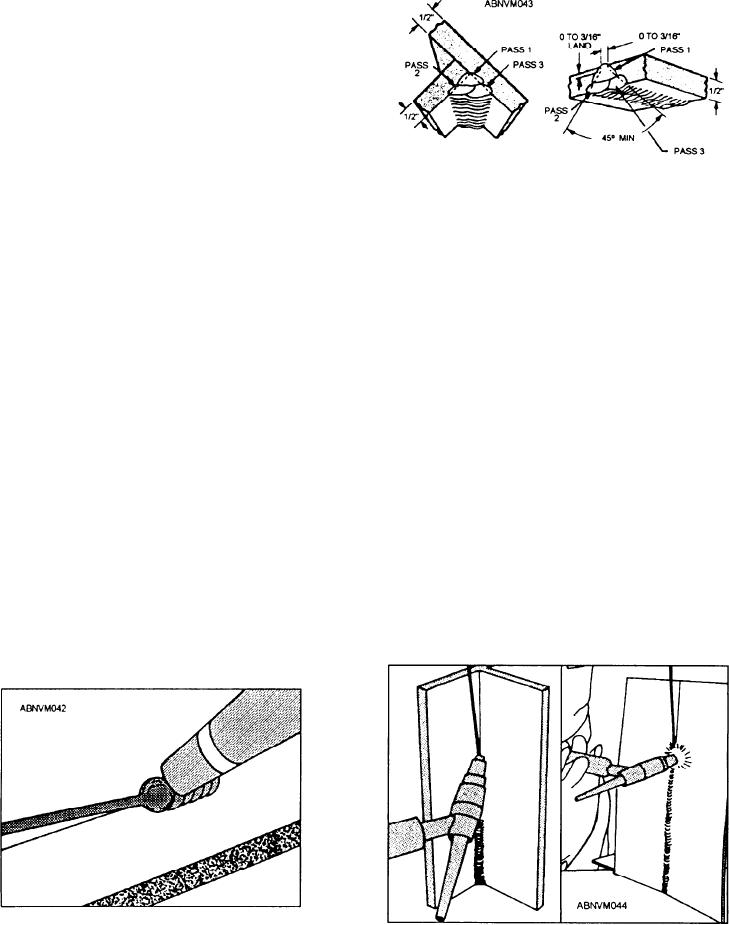

Figure 10-42.--Joint design and weld pass sequence

vertical-position multipass fillet and butt welds.

with superimposed high-frequency current, a GTA

Butt and fillet welds in the vertical position are

welding torch equipped with 3/16-inch diameter

made as shown in figure 10-43.

tungsten electrode, argon gas, and the necessary

accessories.

A l l of the factors presented concerning

out-of-position welding also apply here. Do not use

Prepare the abutting edges of plate as shown in

too high a welding current or deposit too large a

f i g u r e 10-22. Clean and dry the joint area

weld bead. If the molten pool is too large, it will be

thoroughly. Brush with a stainless-steel wire brush

difficult to control. Bead size, filler metal addition,

to remove oxide where the filler metal will be

and bead sequence should be carefully handled to

deposited. Examine and clean the filler rod, if

ensure complete fusion between passes. Some

needed.

welders find that a slight weave in vertical welding

will smooth out the bead. Practice your work until

Regulate the argon gas flow at 35 cubic feet per

it passes satisfactory visual inspection.

hour, and select a welding current from 250 to 320

amperes.

Overhead-Position Multipass

Position sections as shown with all units

Fillet and Butt Welds

supported. Tack weld in the most convenient

This exercise will acquaint you with the

position. Holding jigs may be used. Follow the

technique of overhead-position welding.

weld pass sequence as shown in figure 10-42.

The

Figure 10-41.--Correct position of the welding torch and

Figure 10-43.--Butt and fillet welds made in the vertical

proper addition of the tiller metal to form a weld pool.

position.

10-36