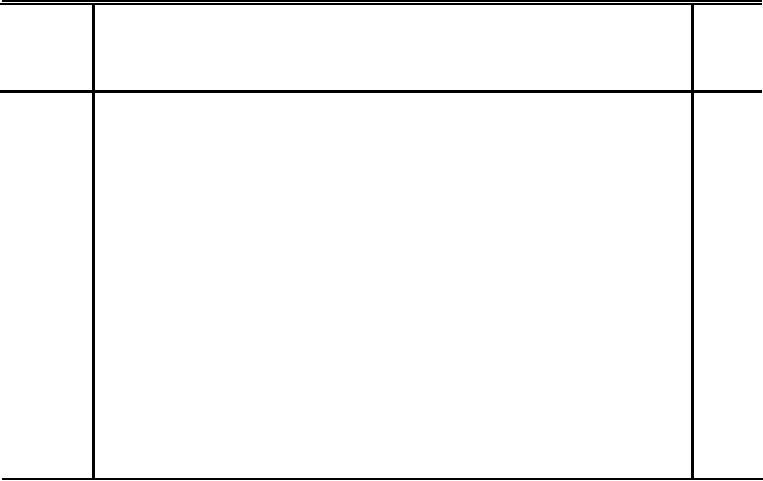

Table 10-8.--Recommended Practices for GTA Welding of Aluminum

(2)

Filler

Dia. of

(3)

Rod

Argon

No. of

Welding

Current

Tungsten

Material

(1)

Dia.

Joint Design

Amps

Electrode

Gas Flow

Passes

Position

Thichness

Inches

AC

Inches

CFH

Inches

70-100

1/16

20

3/32

1

Flat

1/16

Sq. Butt

Horiz & Vert.

Sq. Butt

70-100

1/16

20

3/32

1

Overhead

Sq. Butt

60-90

1/16

25

3/32

1

1

Flat

Sq. Butt

125-160

3/32

20

1/8

1/8

Horiz & Vert.

Sq. Butt

3/32

1

115-150

20

1/8

1

Overhead

Sq. Butt

115-150

3/32

25

1/8

5/32

30

Flat

60 Single Bevel

225-275

3/16

2

1/4

Horiz & Vert.

60 Single Bevel

200-240

5/32

3/16

30

2

3/16

Overhead

100 Single Bevel

210-260

5/32

35

2

Flat

35

60 Single Bevel

325-400

2

1/4

1/4

3/8

Horiz & Vert.

60 Single Bevel

250-320

3/16

35

3

1/4

Overhead

100 Single Bevel

275-350

3/16

3

40

1/4

Flat

3

60 Single Bevel

375-450

35

1/2

1/4

1/4

Horiz & Vert.

60 Single Bevel

250-320

3/16

35

3

1/4

Overhead

100 Single Bevel

275-340

3/16

40

4

1/4

1

Flat

60 Single Bevel

500-600

5/16-3/8

1/4-3/8

35-45

8-10

(1)

See exercises for joint designs.

(2)

For standard (non-thoriated) tungsten electrodes.

(3)

Helium is not generally used on gas tungsten-arc welding; however, gas flow rates for it are slightly

higher than for argon.

Filler Metal

PRACTICE EXERCISES FOR

GTA WELDING

Additional filler metal is not necessary in GTA

welding when enough parent metal is provided by

Now that we have covered various fundamentals

the joint design to form the weld bead. For other

of GTA welding of aluminum, let us turn our

welds, it is often necessary to add filler metal. For

attention to some practical exercises that will help

filler metal in the form of straight length, bare rod

you acquire skill in performing GTA welding

is used for manual welding, while filler metal in wire

operations.

A thorough knowledge of the

form, spool wound is used for automatic welding.

procedures covered in the following projects will aid

you in assignments as the operator on GTA welding

Filler rods of EC, 1100, 4043, 5154, 5183, 5356,

jobs.

5556, and other alloys are available in various

diameters. Take care to see that a compatible filler

Setting Up Equipment

metal is used in welding different aluminum alloys.

Weld craters and longitudinal cracks may result

This exercise in setting up equipment will

from using incorrect filler alloy. Make a special

acquaint you with the equipment and accessories

effort to see that only clean rods are used. Dirty

commonly used in GTA welding. The basic

rods contaminate the weld. Store rods in a hot

equipment and accessories required for GTA

locker or warm dry area and keep them covered.

welding of aluminum are as follows:

10-29