WARNING SIGNS, PLACARDS,

TAGS, LABELS, AND MARKINGS

Warning signs, placards, tags, labels, and suitable

guards/markings should be provided to prevent

personnel from coming into accidental contact with

dangerous equipment; for warning personnel of the

of grinding operations; and for warning personnel of

other dangers that may cause injury to them. Equipment

installations should not be considered complete until

appropriate warning signs have been posted in full view

of operating and maintenance personnel.

Warning signs (red/white) and caution signs

(yellow/black) should be located in an area where

known hazardous conditions exist or may exist. Some

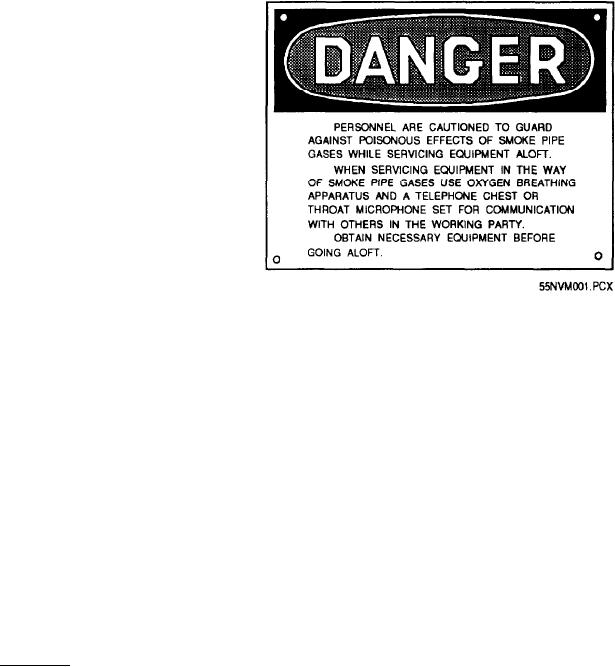

Figure 1-1.--A warning placard.

of the areas that are hazardous aboard ship include

workshops, pump rooms, and machinery spaces.

However, hazards may be encountered anywhere aboard

Remember, once a tag or label is used, it should

ship.

only be removed by signed authorization of the

authorizing officer. You should always follow your

Signs designating an entire space as hazardous must

command's procedures for logging and recording

be posted at eye level or above in full and clear view of

tag-out actions.

entering personnel. Signs designating a specific piece of

equipment as hazardous must be posted on or near

equipment (in full view of the equipment operator) that

Markings consisting of paint or tape are used to

designate safe traffic lanes, operator caution areas,

is particularly dangerous.

operator working areas, and observer safe areas.

Warning placards (fig. l-l) should be located on the

door to the entrance of any space where noise levels are

Safe traffic lanes are designated in workshops.

These lanes start and stop at all exits and entrances for

consistently high, requiring single- or double-hearing

protection. A warning placard should also be displayed

workshops and are marked by continuous white lines,

3 inches wide, painted on the deck.

on all portable equipment capable of emitting noise in

excess of 84 dB(A) when operated. Remember that the

Operator caution areas, operator working areas, and

messages are aimed at YOU. It is your responsibility to

observer safe areas are designated for each equipment

"read and heed."

working area deemed hazardous. Operator caution areas

are marked by a continuous yellow tine, 3 inches wide,

Tags and labels are used in the Navy to identify a

defective piece of equipment or instrument. Tags and

outlining the caution area. Operator work areas are

marked by painting the deck yellow in areas where it is

labels are also used to ensure the safety of personnel

and to prevent improper operation of equipment. They

safe for an operator of machinery or equipment. The

will be posted according to authorized procedures and

outer perimeter of this area is designated by alternate

must not be removed or violated without proper

black and yellow lines, or checkerboard pattern, 3

authorization and adequate knowledge of the

inches wide. Observer safe areas are designated as all

consequences.

areas outside of this perimeter and are the normal color

of the deck within the space.

The use of tags and labels is not a substitute for

other safety measures, such as locking valves or

Eye hazardous areas are marked with a black and

removing fuses from a fuse panel. Also, tags or labels

yellow checkerboard, or chevron, pattern and a label

associated with tag-out procedures must never be used

plate made up of black letters on a yellow background

for anything other than their intended purpose.

that reads: "WARNING EYE HAZARD."

1-4